Introduction

If you read my previous piece on fitting Lipo packs into Tamiya "packed" battery cases, you'll know that the 2S (7.4v) Lipo packs worked well, but the 1S (3.7v) packs just didn't work in 1/10th offroaders. I don't propose to cover too much of the theory, making old cases usable, or making your own decals again - this is more about soldering up individual Lipo cells into usable packs. This does have an advantage over buying premade packs - you can make better use of the space available inside a Tamiya style case, maximising the battery capacity: 2200mAH instead of 1600mAH, given the current state of the art in capacities & sizes (June 2013).

Things you'll need:

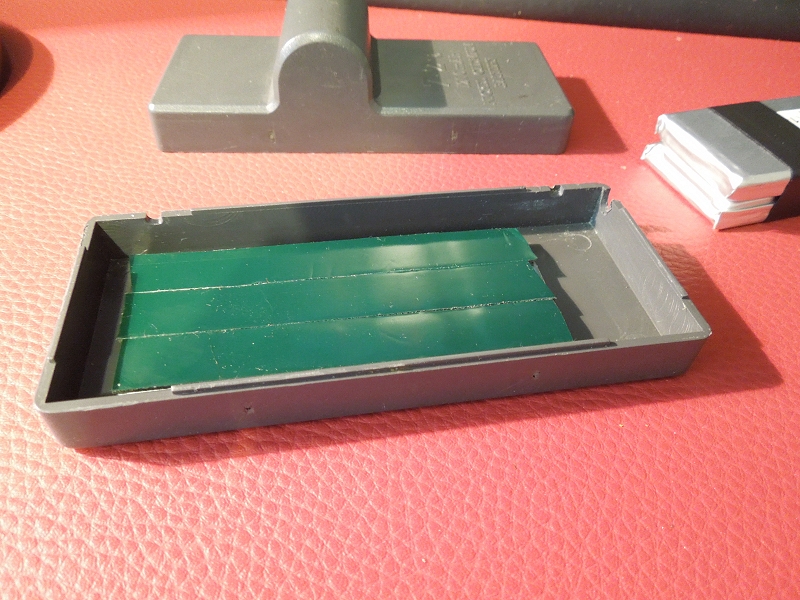

- Tamiya battery pack cases

- Heatshrink tube (and a means of shrinking it), double sided tape, servo tape, insulation tape

- Stick on wheel weights

- Soldering iron, solder, etc

- Chunky red & black wire and male XT60 plugs for the power connector

- Thinner red, black & some other colour and male 3-way JST-XH connectors for the balance leads - or cheat like I did this time & buy premade 2S balance leads

- Individual Lipo cells: I used Turnigy bare 1S cells bought from Hobbyking - the 2200mAH, 20C version. The 2200mAH, 40C version could also be used as they have very similar dimensions, but the larger capacity cells (3300mAH and 5000mAH) are too long.

Theory

Given the horror stories about Lipo batteries (which, dare I suggest, are usually down to using soft cased packs, or not taking proper precautions when charging), and the added complexity of a balance lead, I can understand some reluctance to solder up your own packs - but with a bit of forethought & care there's no reason it should be a problem.

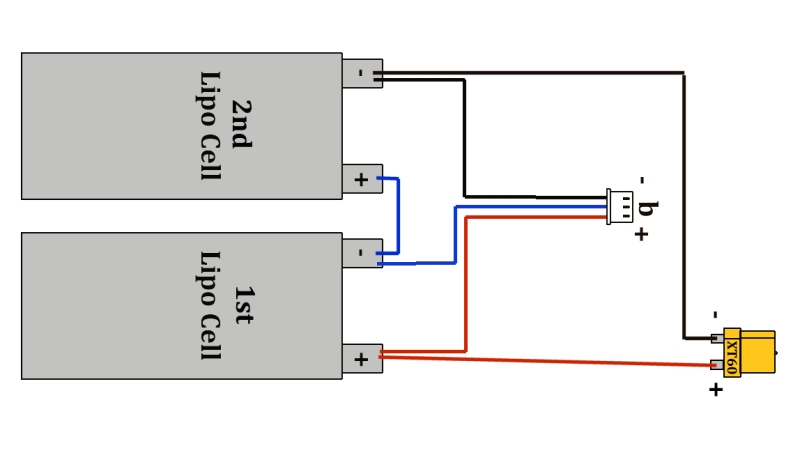

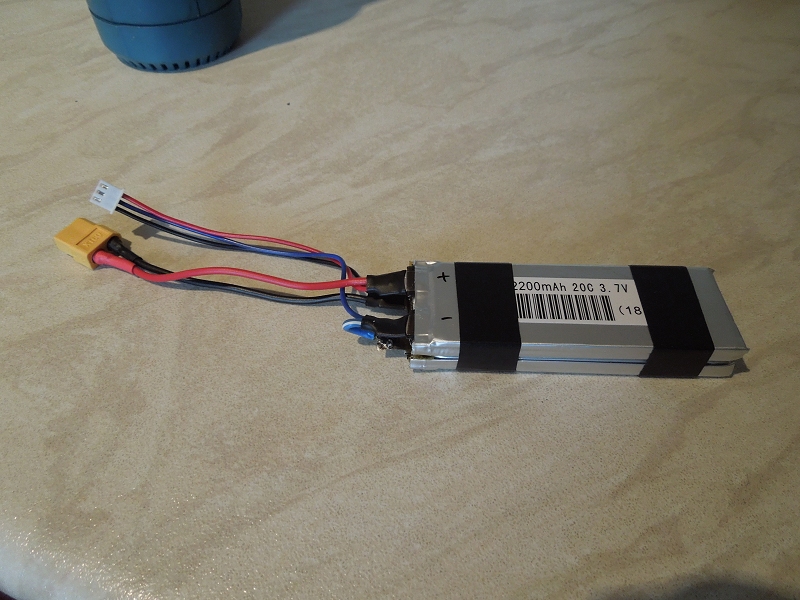

For a 2S pack, there are basically 4 components: two cells, the balance plug/lead, and the power connector/lead.

The easy bit (for anyone used to the concept of cells in series) is that:

- The red (positive, +ve) wire from the power connector goes to the positive terminal (or tab) on the first Lipo cell;

- The negative (-ve) terminal from that first cell is joined to the +ve tab on the 2nd cell by a bit of wire (blue in my examples);

- The black (-ve) wire on the power connector is joined to the negative terminal on the 2nd cell.

This completes the circuit correctly so you have a useable battery - but not one that can be balance charged, or have a low voltage warning buzzer fitted.

For that you need a balance lead too, which is wired with:

- The red (+ve) wire going to the +ve terminal on the 1st cell;

- The black (-ve) wire going to the -ve terminal on the 2nd cell; and

- The balance (blue) wire going to the connection between the two cells - this can be part way along the joint wire, or on the -ve terminal of the 1st cell, or on the +ve terminal on the 2nd cell - it's all electrically the same.

In practice, this means you have 4 connections to make:

- +ve on 1st cell: red wires from the power & balance plugs

- -ve on 1st cell: blue wires from the balance plug + short (blue) link wire

- +ve on 2nd cell: other end of that (blue) wire

- -ve on 2nd cell: black wires from the power & balance plugs

Apologies for going on (and for the indifferent quality of my block diagram), but it's very important to get the wiring correct - get it wrong & you could cause a short circuit, very rapid overheating & a fire you can't put out.

If you're not clear you shouldn't proceed any further - though it might be worth checking out scriptasylum.com/rc_speed/lipo.html & configuring the examples there.

In Practice

I don't want to be too prescriptive, this is just how I did it:

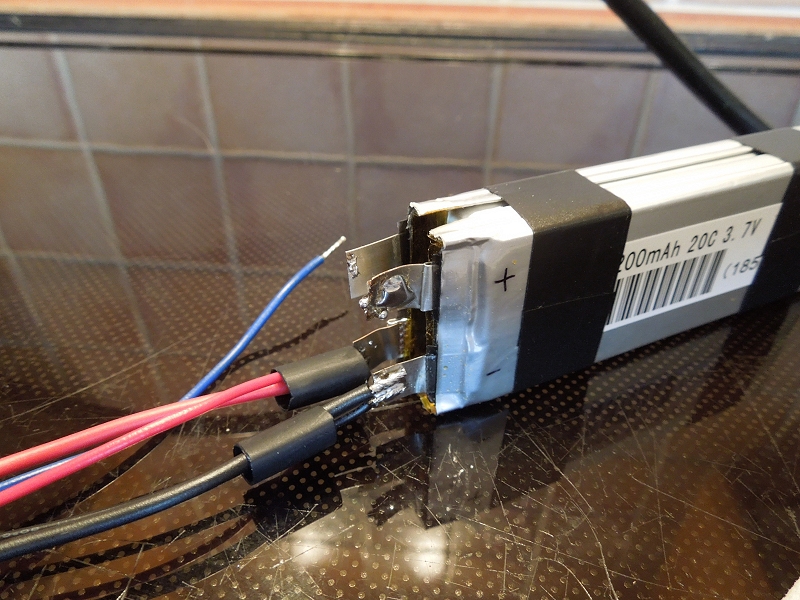

1. Tin the outside of the tabs on each Lipo cell ... it's a compromise between getting enough solder on over a wide enough area without heating the battery for too long

2. Invert one cell (so the tabs are as far away from each other as possible) and use double sided tape to hold the cells together ...

3. ... a bit of extra insulation tape won't hurt either.

4. Having assembled the power connector & balance leads (if necessary), tin the ends of each wire, slip a bit of heatshrink tubing over both red wire & solder them to the +ve terminal on the 1st Lipo cell.

5. Repeat (remembering the heatshrink) for both black wires - these attach to the -ve terminal on the 2nd Lipo cell.

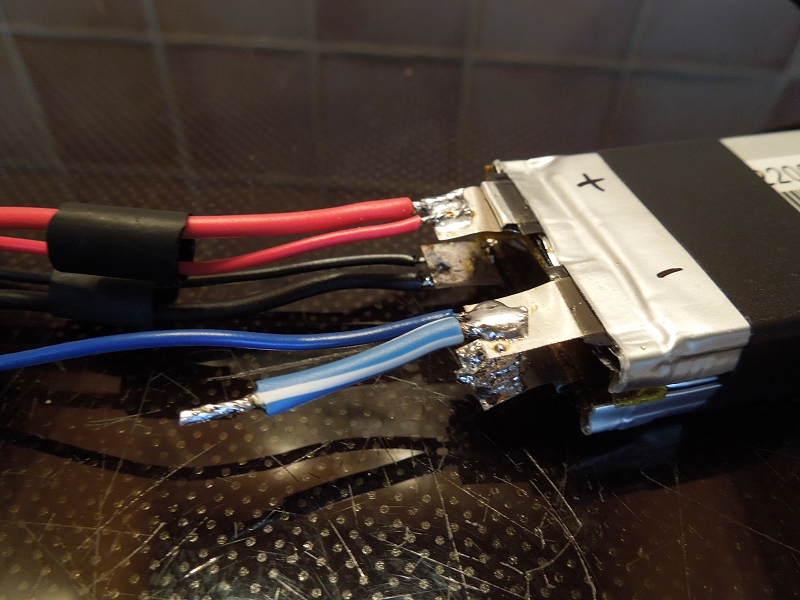

6. Remembering to slip on a bit of heatshrink tube on the wire from the centre pin on the balance connector (blue here), solder that & a length of wire on to the -ve tab on the 1st cell.

7. I was worried about space, so used a very short bit of wire for the connection between the two cells ... the wire turned out to be too short to take an extra bit of heatshrink...

8. In the end I needn't have worried that much about the space inside the battery case... One bare terminal is not ideal, but there's little risk of it shorting as all the others are covered.

Either way, the final joint to solder is the other end of the link wire to the +ve tab on the 2nd cell.

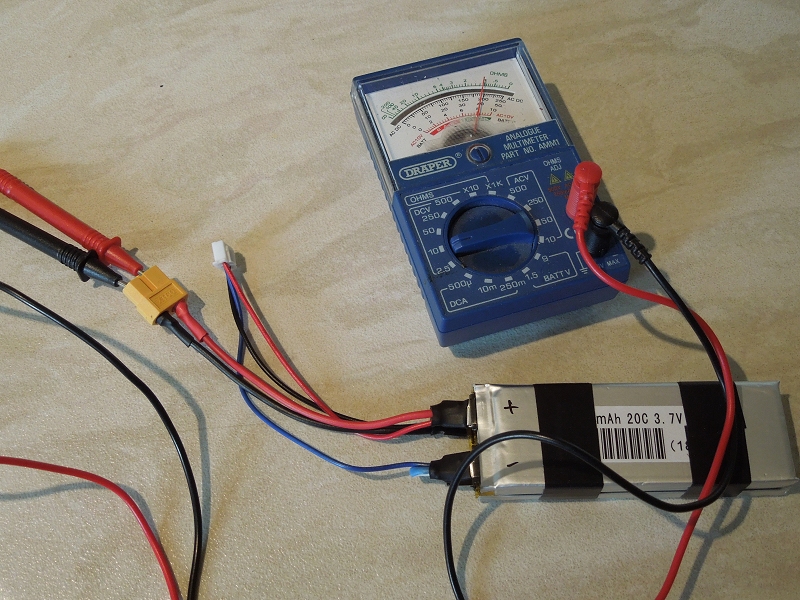

9. Testing the pack for the right voltages at the right points will give extra peace of mind - using an old skool analogue multimeter should give you the following voltages at these points:

• Red probe on +ve terminal of power connector, black probe on -ve terminal of power connector: just under 8v (whole pack voltage)

• Red probe on +ve terminal of balance plug, black probe on -ve terminal of balance plug: again, just under 8v (whole pack voltage)

• Red probe on +ve terminal of balance plug, black on centre balance terminal: under 4v (1st cell voltage)

• Red probe on balance terminal of balance plug, black on -ve: under 4v (2nd cell voltage)

Also check you've got the polarity of the power connector right: red to "+", black to "-" ... I managed to get the leads the wrong way round on one (out of six) & didn't pick it up until I got a "reverse polarity" warning on the charger - doh!

10. Weights are optional - but as the suspension of the cars this sort of pack will be used in was designed with the weight of a 5 or 6 cell Ni-Cad pack in mind, making up a bit of the difference is a Good Thing in my view ... these are held in with double sided foam tape (aka servo tape) - there's no way they're coming off in a hurry

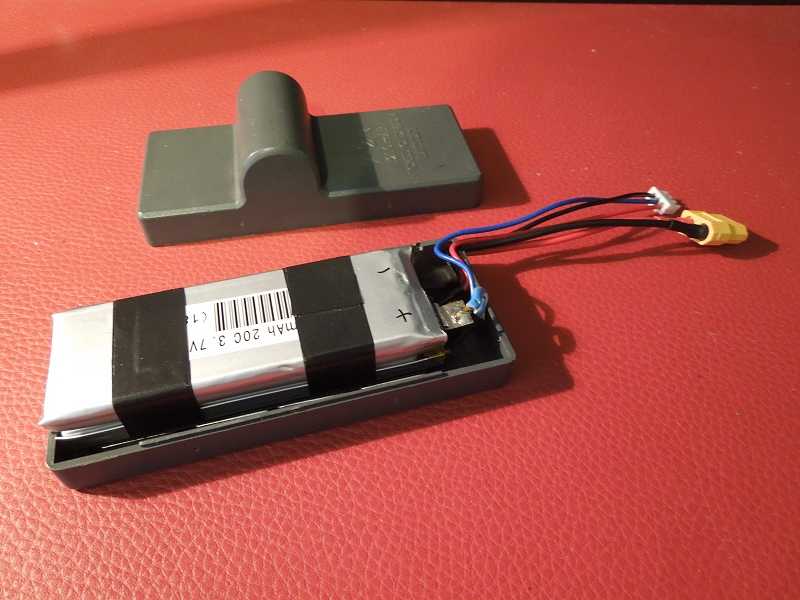

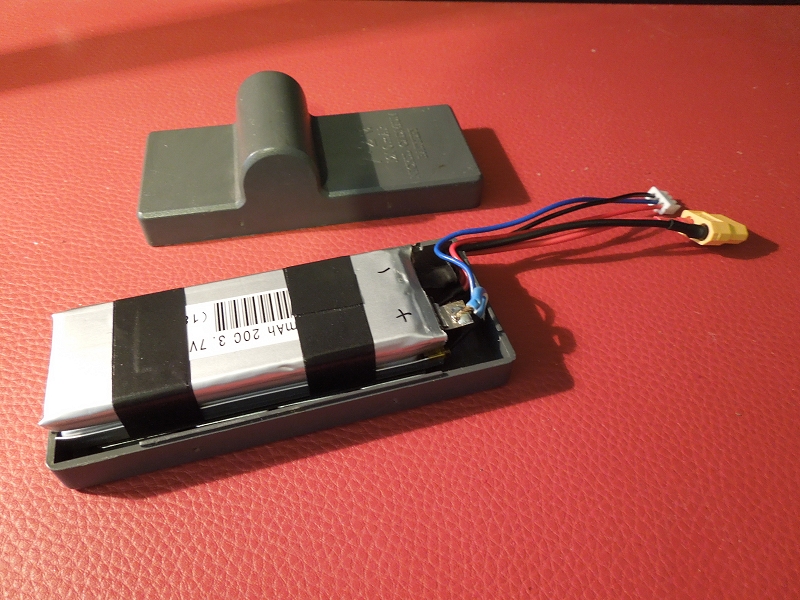

11. Use more servo tape to hold the battery in ...

12. ... again, it's not coming off in hurry so be sure you have the cells lined up correctly before you commit; wires & tabs did need a little persuasion to fit.

13. Stick the casing back together (I use regular plastic kit "poly" glue), using tape to clamp the halves overnight.

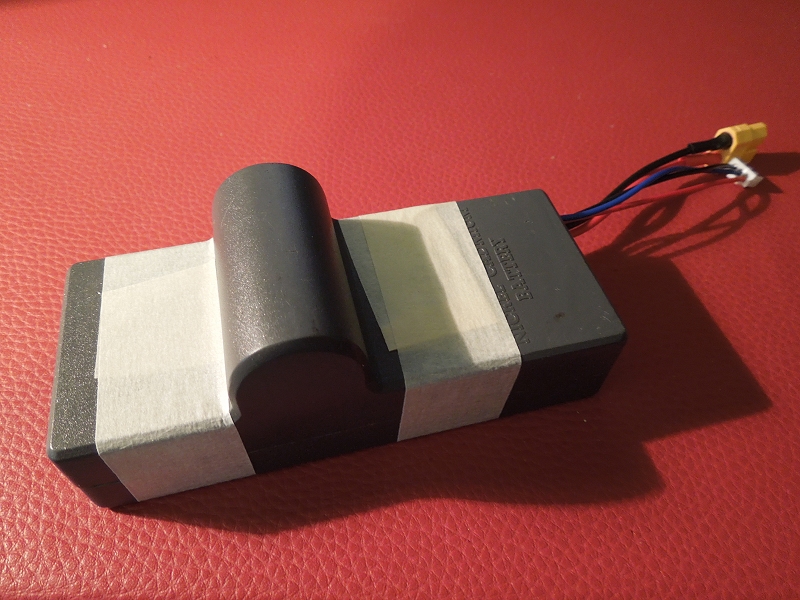

14. The XT60 plug & balance lead should be a bit of a clue that it's no longer a 7.2v or 6v Ni-Cad pack, but clear labelling will help, especially when it comes to setting "C" ratings for charging. I made stickers in the style of traditional Tamiya packs. Note the grey hump pack - It wasn't just Tamiya that made "packed" batteries back in the day - but very, very few seem to have survived.

15. If you're not going to use the pack for a while you should give it a "storage" charge. Make sure you give it a "Balance" charge before first proper use.

________________________

Written by TB member Jonny Retro