TOPIC:

Unimat SL Micro Lathe 10 years 5 months ago #25936

|

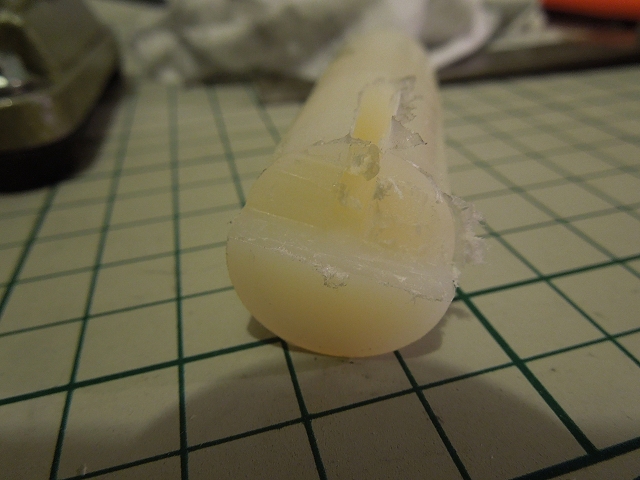

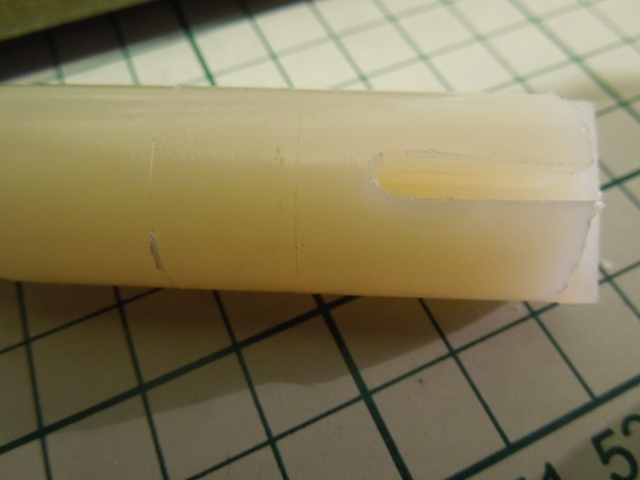

I had a quick go at milling ... the bit of nylon I wanted to mill was (at 31mm) too big for the vice, but while I had it set up I thought I'd have a go to see if it was worth upgrading ... it's not

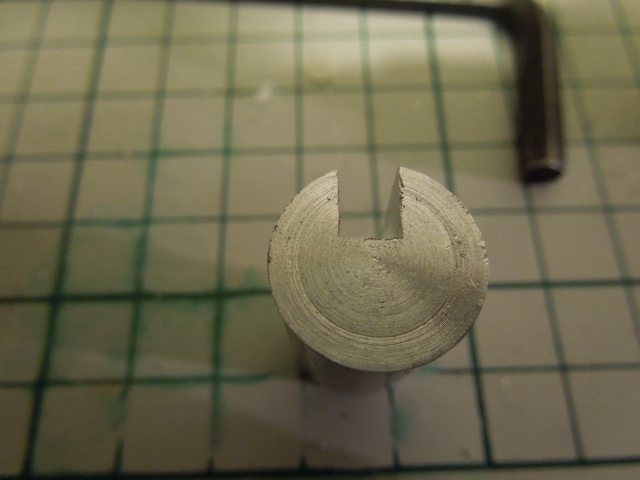

It's a bit better on aluminium, but there's just too much flex in the machine & no way to accurate set the depth of cut Note the orange belts - of the 3 sets of black ones the unimat came with, 2 have already failed so I'm hoping these will be better

The following user(s) Liked this: jord001

|

|

Please Log in to join the conversation. |

Unimat SL Micro Lathe 10 years 4 months ago #26270

|

Cool

The following user(s) Liked this: jord001

|

|

Please Log in to join the conversation. |

Unimat SL Micro Lathe 10 years 4 months ago #26317

|

I have a few (HSS?) 1/4" bits that came with mine, + a set of brazed carbide 6x6mm tools. I prefer the carbide ones, even if they do need a bit of shimming to get the tip height correct. I really can't get on with the parting off tool, but using it without shims & only taking very shallow cuts improves things a little. Angles: very pointy for rough work, less so for finishing. Going too straight is a recipe for chatter, stalling, and getting your work ripped out of the chuck Getting as much rigidity into your setup is important, so have the tools sticking out of the toolpost as short as possible.

The following user(s) Liked this: jord001

|

|

Please Log in to join the conversation. |

Unimat SL Micro Lathe 10 years 4 months ago #26320

|

Thx Jonny, she is standing right next to me on the table now, waiting for some 1on1 quality time.

Will post some pics later on, have to build a Ikea shelving unit first. More room for RC stuff :-D

The following user(s) Liked this: jord001

|

|

|

Please Log in to join the conversation. |

Time to create page: 0.142 seconds