TOPIC:

Unimat SL Micro Lathe 9 years 3 months ago #32828

A buddy of mine has that exact machine u just bought. Still looks new after 44 years. galaxy note edge hülle |

|

|

Please Log in to join the conversation.

Last edit: by Friedel.

|

Unimat SL Micro Lathe 8 years 10 months ago #34503

|

Have you tried using the 20mm riser yet? I have one on the way & have been wondering how to give the toolpost & tailstock a corresponding lift |

|

Please Log in to join the conversation. |

Unimat SL Micro Lathe 8 years 10 months ago #34559

|

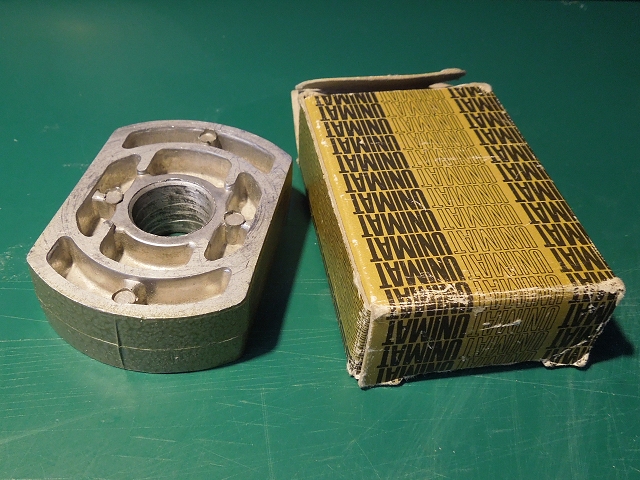

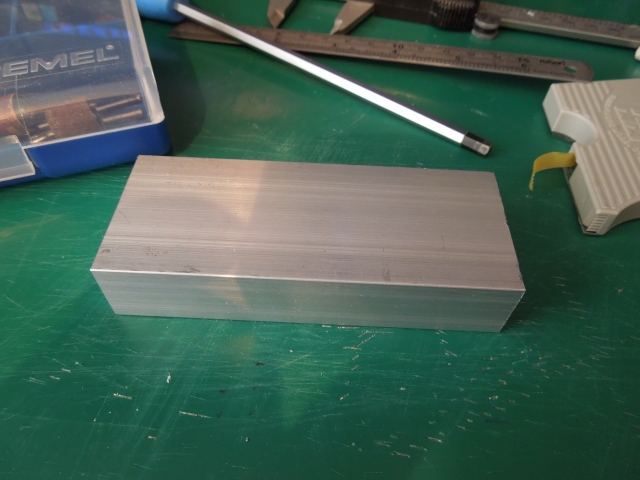

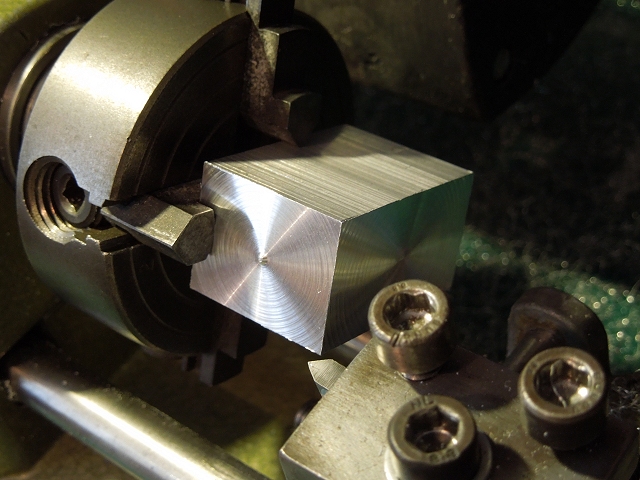

The riser arrived so I used a suitable chunk of aluminium to give the toolpost a matching lift (a 4-jaw independent chuck is the most useful upgrade you can have IMO) ... 62mm Bush Devil wheel could be spun without the risers, but you couldn't get the carriage underneath & could only tickle the faces.

You could possibly get something up to 74mm in now, but only with only the tiniest bit of a tool showing in the holder. Overall I think a riser will make the Unimat a bit more useable, but without really increasing capacity that much - you can't do anything to move the toolpost further away from the work, so that & the small chuck having a limited grip restrict capacity.

The following user(s) Liked this: jord001

|

|

Please Log in to join the conversation. |

Unimat SL Micro Lathe 8 years 10 months ago #34560

|

Couldn't you make an offset block that extends further back to move the tool holder back?

|

|

Please Log in to join the conversation. |

Unimat SL Micro Lathe 8 years 10 months ago #34562

|

TBH I don't think it would help - things are so tight the top slide of the carriage would get in the way even if you could step the toolpost back a bit. |

|

Please Log in to join the conversation. |

Unimat SL Micro Lathe 7 years 4 months ago #41726

|

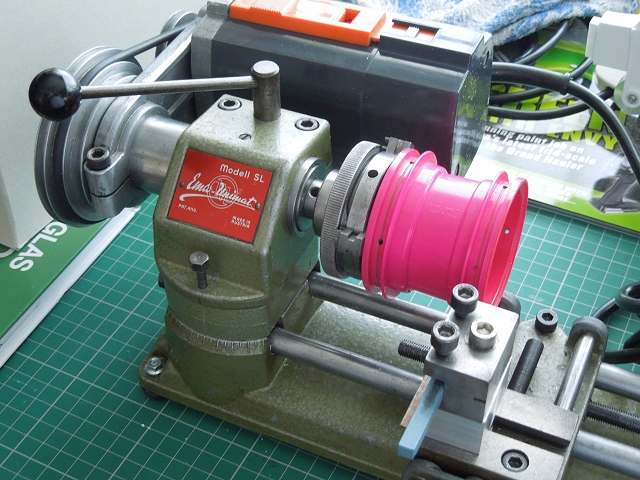

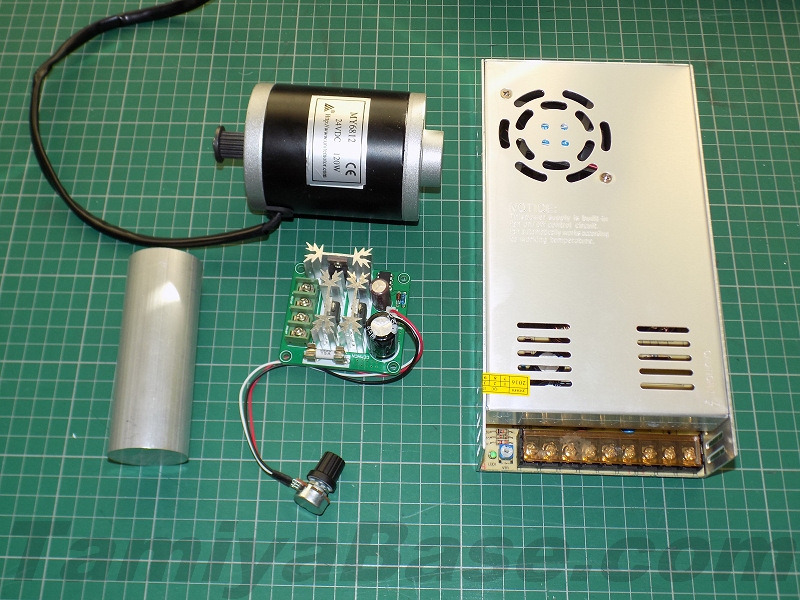

The motor has given up after a mere 40+ years, I suspect the insulation on one or more of the field coils is failing

This is hardly a complete guide, but it does at least give suggestions & have pictures - motor is a Chinese 24v DC scooter motor rated at 120W, along with a suitable PSU & speed control. The motor has three mount holes but only one a time lines up with the Unimat bracket, and it's fitted (hopefully not too well) with a small pinion for a toothed belt. I needed to make a new pulley, so the motor is currently hanging on by one screw & the drive belt running on masking tape over the belt (which got burned off the first time I stalled the chuck). This is as far as I've got, two of the wires on the speed control have failed so need resoldering, then the new pulley needs drilling & tapping for a grub screw, and the motor needs the existing pinion removing & the faceplate removing, drilling & tapping for another screw mount. I may not make a "proper" three step pulley for the new motor as I tended to only run the lathe at 1600rpm (middle step on motor pulley to middle step on machine pulley) anyway.

The following user(s) Liked this: jord001

|

|

Please Log in to join the conversation. |

Unimat SL Micro Lathe 7 years 3 months ago #41844

|

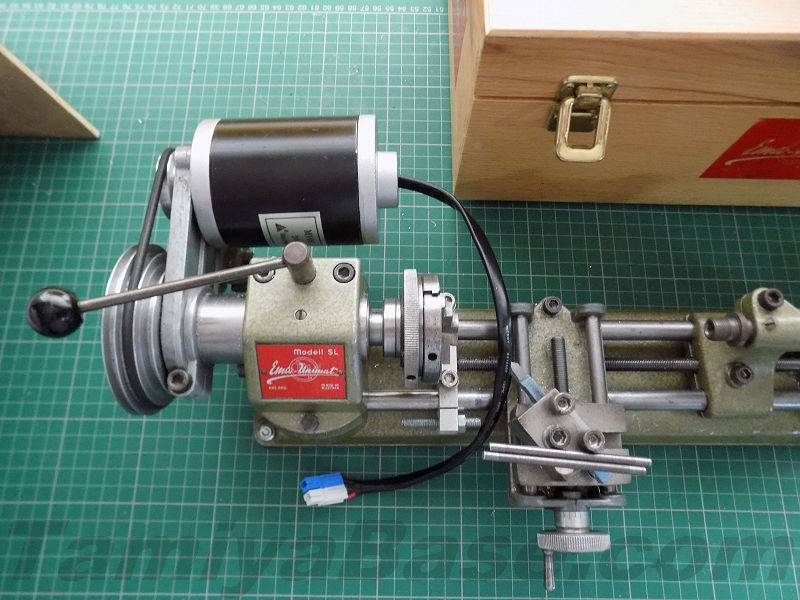

I did finish this - the unwanted pinion came off the new motor witth the aid of a 2-legged hub puller & a bit of angle iron with a notch filed out, the motor then had to come apart to drill/tap an extra mounting hole. It looks quite tidy fitted.

The separate PSU means it's no longer as compact as before, but I've fitted the speed control into a styrene sheet box stuck to the PSU, in practice it means I can plop the combined unit some way off to the right of the lathe in use, then unplug it for easier tidying away |

|

Please Log in to join the conversation. |

Time to create page: 0.166 seconds