TOPIC:

Home Vac Former For making RC car bodies 3 years 9 months ago #60589

thanks! I'm still trying to improve it too. At the moment I an experimenting with making resin casts instead of plaster. Plus I and thinking of replacing the solenoids I have with pneumatic ones. cool, you can still achieve very good results with very domestic gear. You only really need two things, the right temp and good suction that gets sealed around the edge. A good vacuum cleaner will get you there for PETG, HIPS and maybe even ABS. ABS is a good choice as it quite durable, but you'll need a decent control of your temp and you can't get it in clear. So no windows or you cut them out. ABS can also be worked a bit afterwards. So you can sand, drill etc afterwards. yeah, lexan is the tricky one, there is only about a 5 degree temperature window for it to soften, so you need very good temp control. Plus its prone to forming bubbles if its heated too quickly. I quite like PETG, its very easy to form and has some durability to it. HIPS is good too, but not very structural (it will shatter), but for things like interior cockpits its a good choice. I'm really only sticking to ABS, PETG and HIPS, I'm not too keen on PVC, and didn't have a lot of luck with it. My temp was off, which didn't help, but I don't think its a very durable plastic for RC use. You only really see it used on the cheapest RC bodies. I don't think there is any UV stabilisers in the sheets you can get, so any I have seen many go brittle after a few years (well that is at least my experience). Lexan is the best of course, as its the toughest, but it needs very precise temp control and suction. I think it would be difficult to get good consistent results on a home setup. I've also found it quite difficult to get hold of. I can get 0.375 mm and a 1.5 mm roofing grade, but nothing in-between in Australia. Whereabouts are you? please do! |

|

|

Please Log in to join the conversation. |

Home Vac Former For making RC car bodies 8 months 1 day ago #76067

|

Superb thread!

Thanks Johann! I buy kits to built and ru(i)n them

|

|

Please Log in to join the conversation. |

Home Vac Former For making RC car bodies 8 months 1 day ago #76068

|

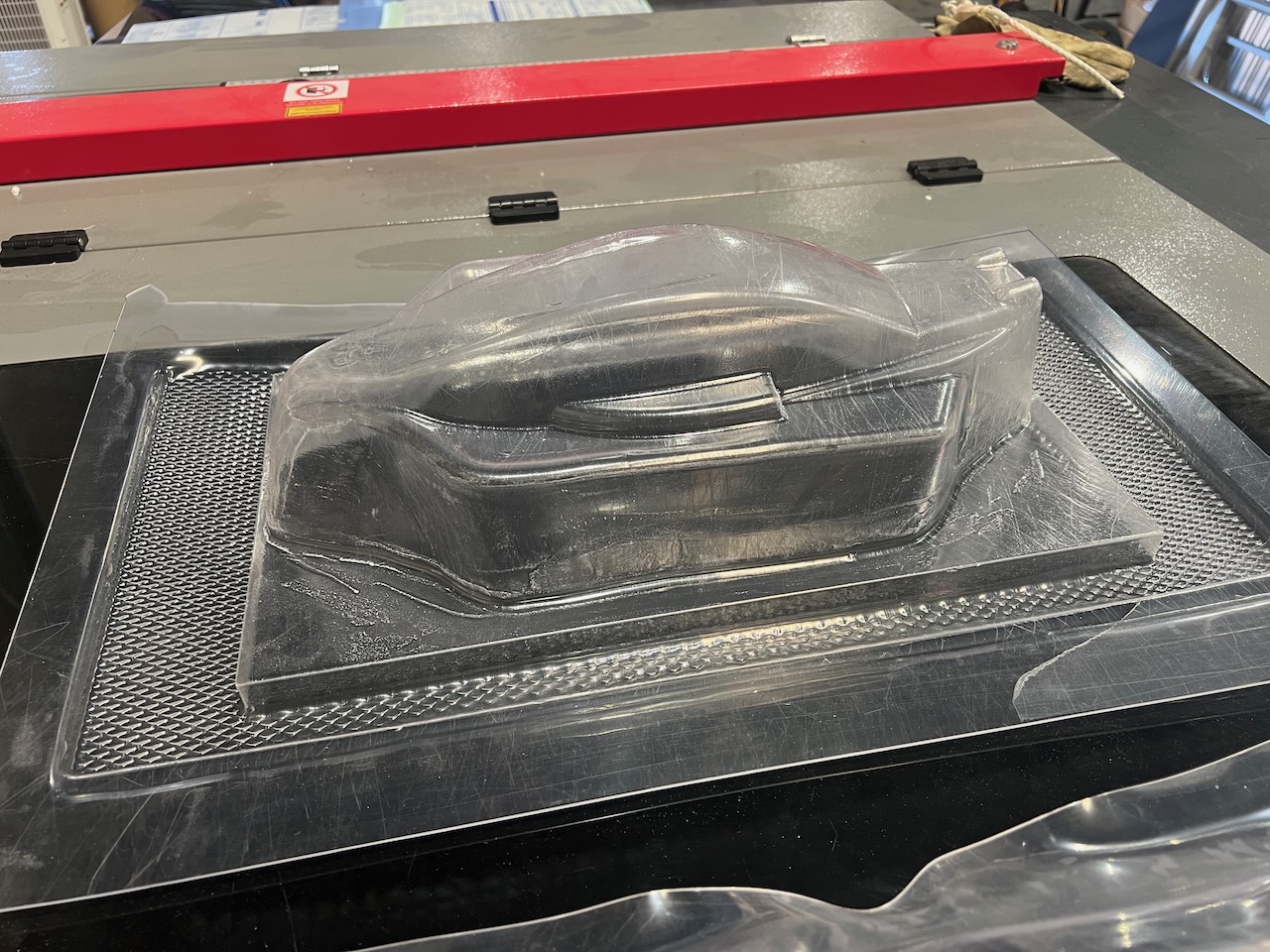

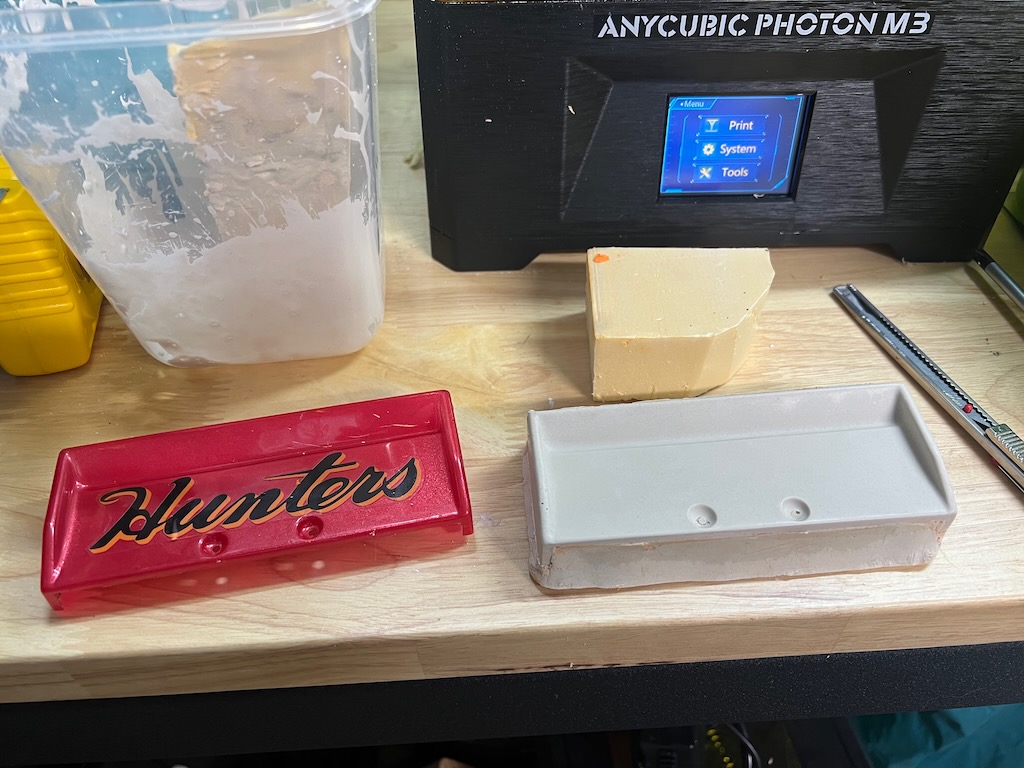

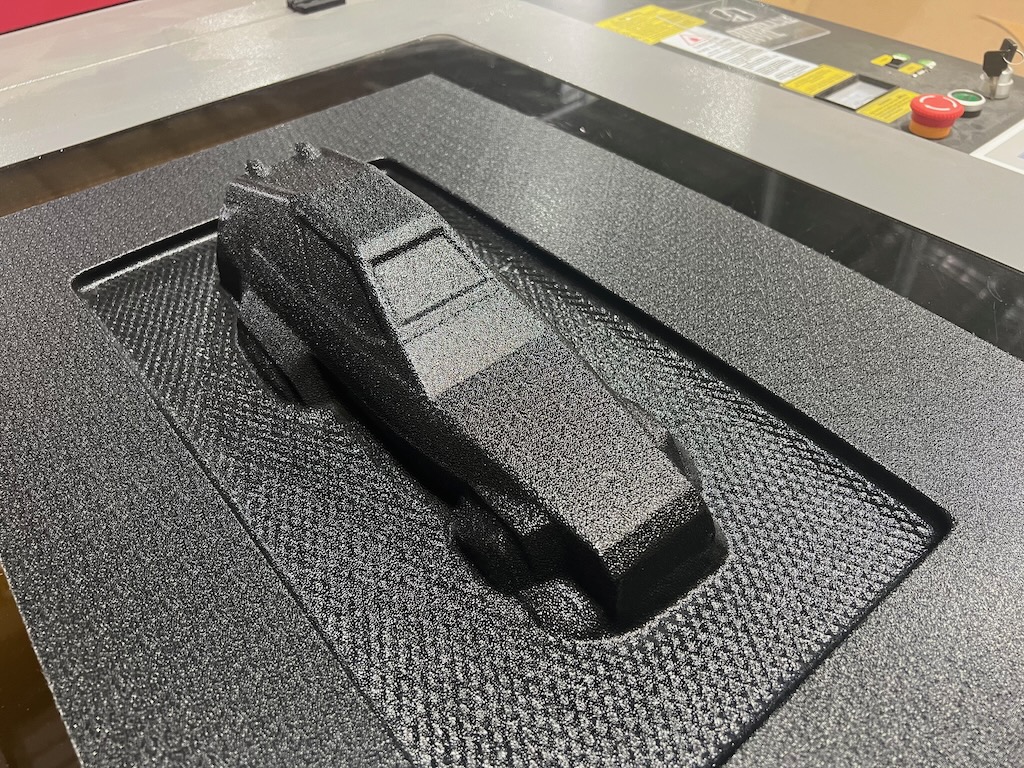

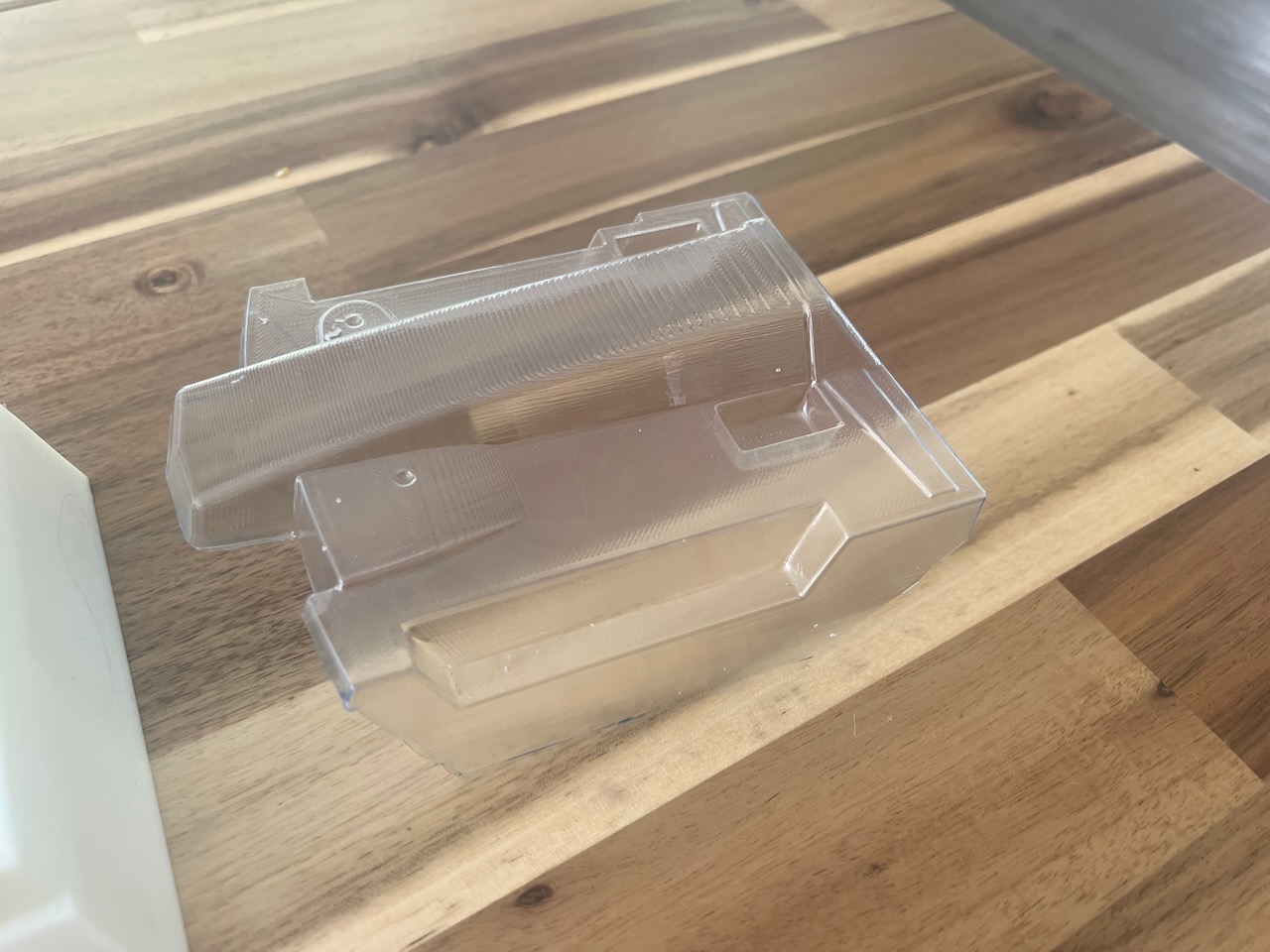

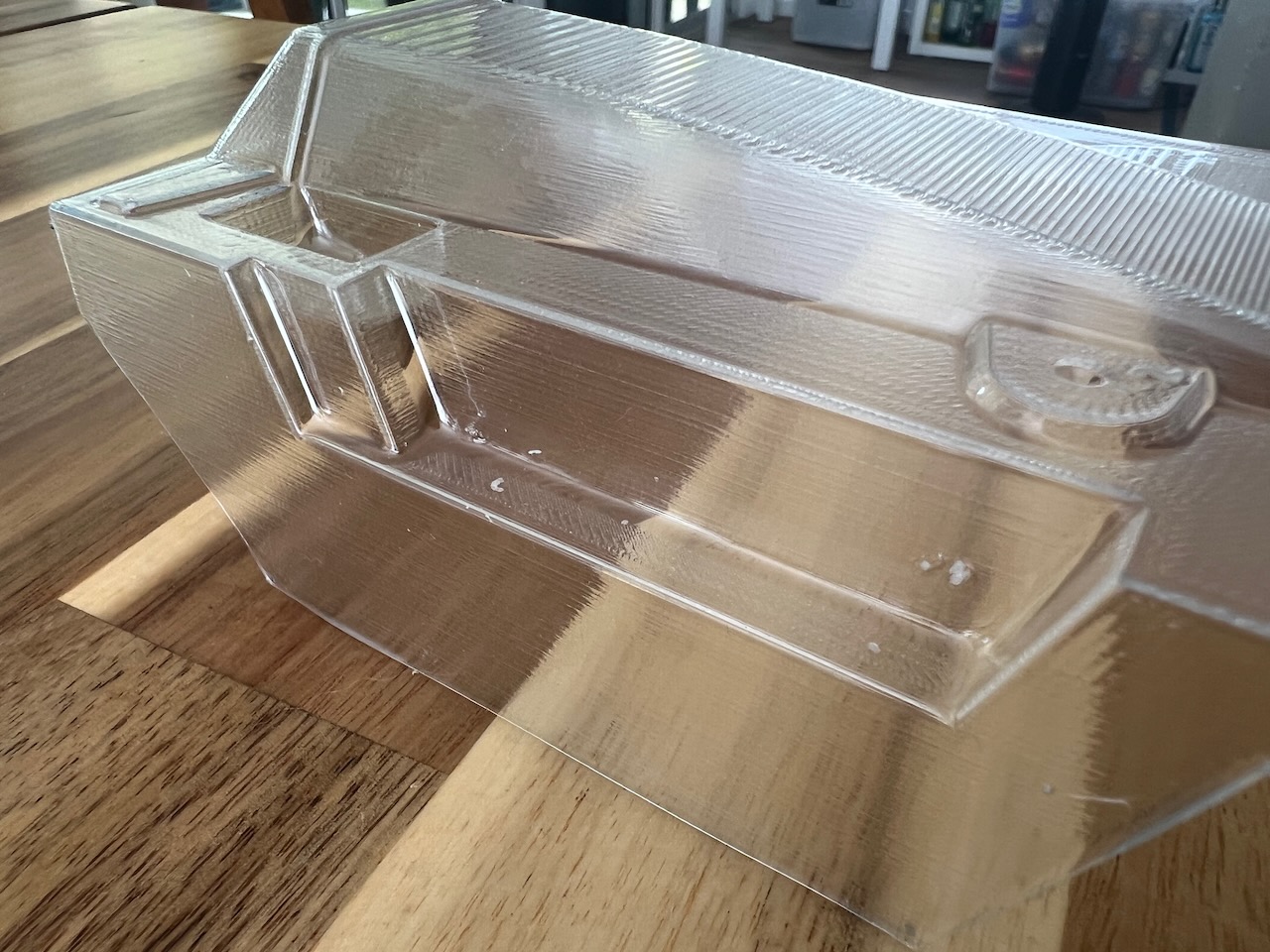

I also took some plaster casts from a Mariu Hunter body this time I tried using ABS, this one is called "hair cell" as it has a pattern on one side and gloss on the other and I'd also done some testing with 3D printed bodies, this one was the test for Silvertriple, using a 0.75 mm I think PETG. 3D printing molds is something I'd eventually like to do more of. |

|

|

Please Log in to join the conversation. |

Home Vac Former For making RC car bodies 8 months 1 day ago #76073

|

Fantastic Johann

|

|

Please Log in to join the conversation. |

Home Vac Former For making RC car bodies 7 months 4 weeks ago #76103

|

Thats great to see. I have 1 question regarding your printed mold parts. How thick are your walls on the printed parts. What kind of infill do you use. What material? so many questions....

I want to convert my 3d models to moldable parts too. Thank you in advance, Lem |

|

|

Please Log in to join the conversation. |

Home Vac Former For making RC car bodies 7 months 4 weeks ago #76104

|

Thick enough, and full : You need to print it in a material that is the higher temp possible, but not the same material as you plan to vacform...

I buy kits to built and ru(i)n them

The following user(s) Liked this: Lemsko

|

|

Please Log in to join the conversation. |

Home Vac Former For making RC car bodies 7 months 4 weeks ago #76108

|

Hi Lemsko,

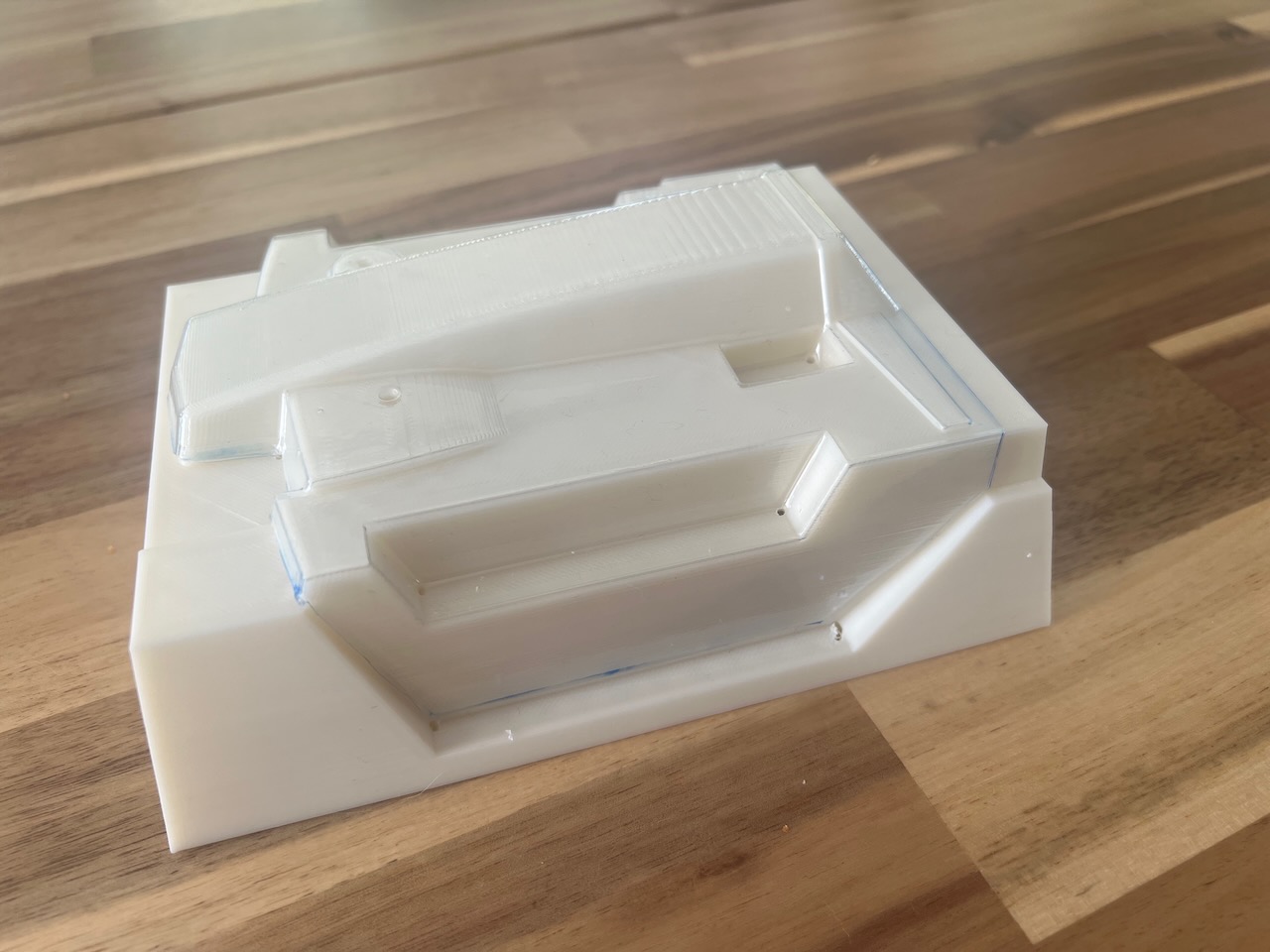

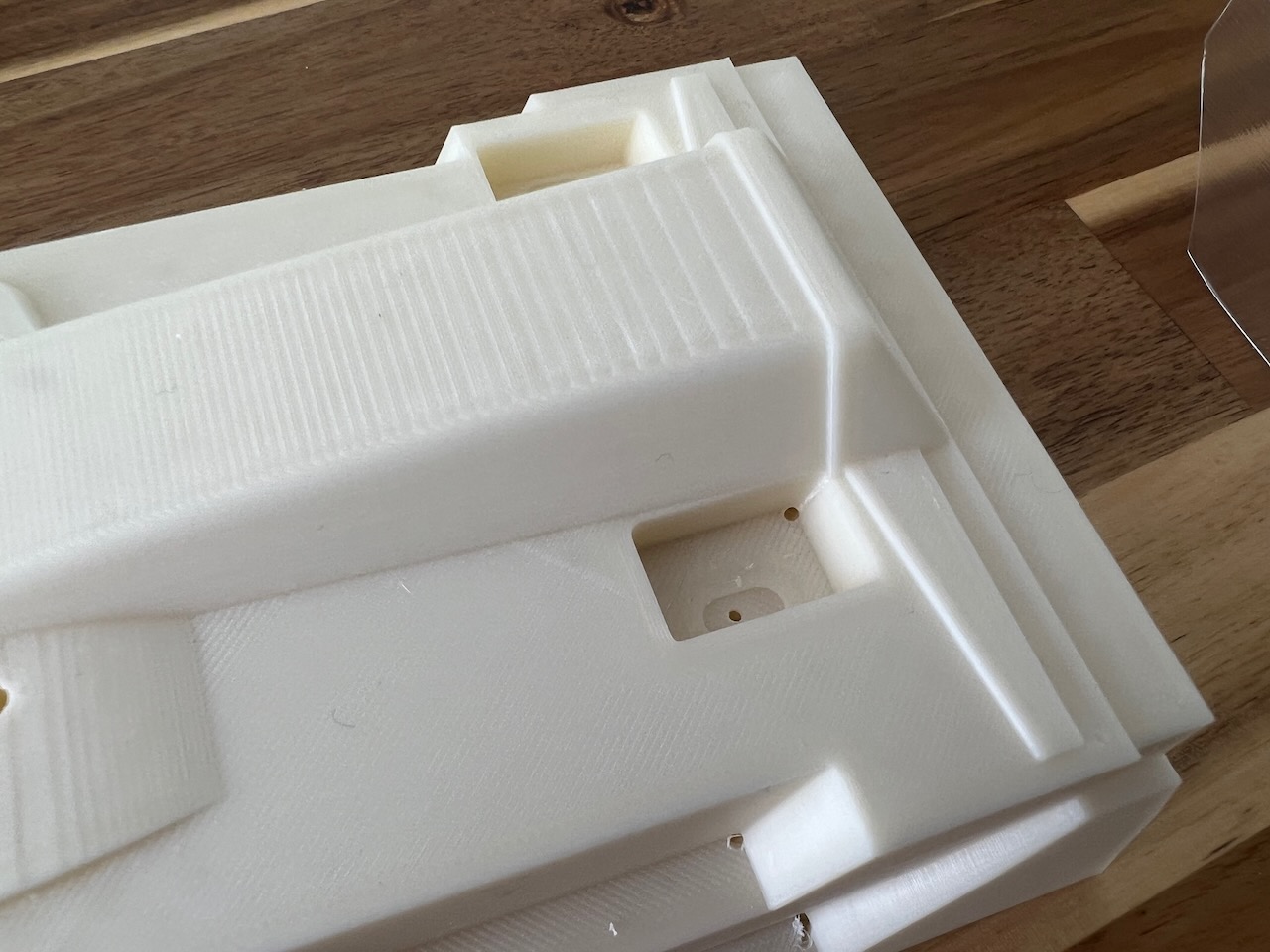

depending on how many you want to make, and what material you want to form at, you can get away with a low temp plastic like PLA, but you'll only get one to two got before it starts to warp. But it is a cheap way to test what you are forming. Ideally you'll want the melting temp on what you are printing to be higher than what you are vac forming with. For the Nichimo body I used ABS, it'll last a fair while, and I vac formed with PETG, polycarbonate would be a bit harder. The walls I made about 10 mm thick. You don't need to go crazy with the infill, something like about 50% should be plenty, but instead up the number of shells though, you'll want that outer shell at least a couple of mm thick to handle the sudden input of heat. You'll also want to smooth the surface, as you get all the line details of the 3D print in the vac form. Spray putty is good there as it also helps seal surface. The other option is to resin print with a high temp resin, I've tried this a couple of times and you get can surfaces that need a lot less prep. And you'll want to add vent holes for any deep recess or corners to help pull in the shape. |

|

|

Please Log in to join the conversation. |

Home Vac Former For making RC car bodies 7 months 4 weeks ago #76109

|

Thank you for the detailed answer. My Hotend only goes to 250°. My plan was to use HIPS, which is my favourite material so far. Sealing it with high temp resin is a great idea i hadnt in mind.

How does paint stick on PETG?

The following user(s) Liked this: 1972 LeMansGT Jim

|

|

|

Please Log in to join the conversation. |