TOPIC:

Boxford 4.5” x 17” Precision Plain Lathe 4 years 9 months ago #55966

|

|

|

Please Log in to join the conversation. |

Boxford 4.5” x 17” Precision Plain Lathe 4 years 9 months ago #55988

|

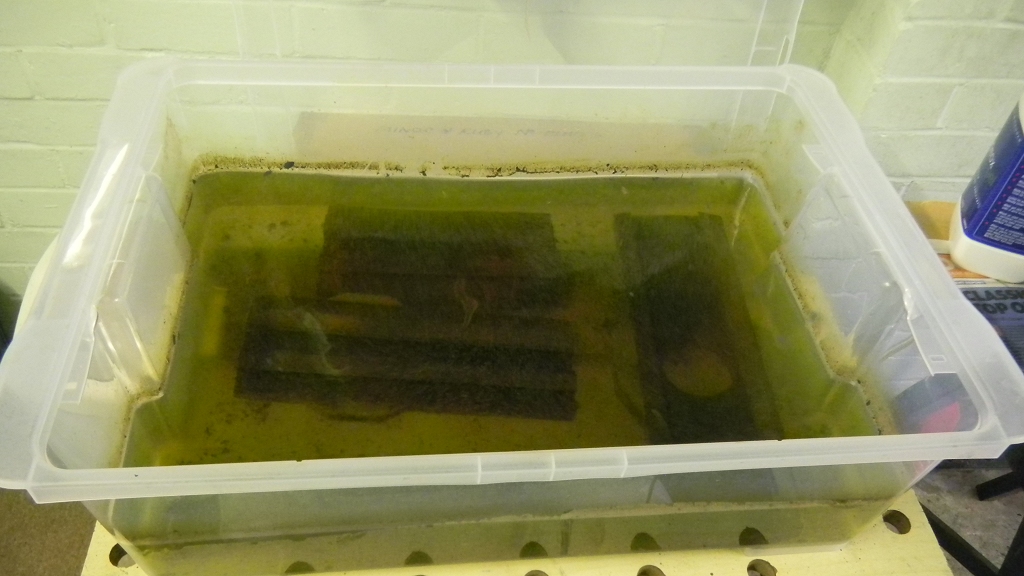

With the first batch of rusty stuff soaking in a bath of Bilt Hamber Deox C (and the motor casing sitting in another tub, daubed with the gel version), I felt safe to attempt some maths …

I’ve been looking at pulley ratios & what sort of rpm I can be expecting on the lathe, plus getting a suitable drive belt to replace the canvas one that came wrapped around the headstock (which was 46 & 5/16 “ (1175mm) long by 1” (25mm) wide). The steps on the motor pulley are 6 & 1/16th", 9 & 1/2", and 13 & 1/2" circumference (154, 241 & 342mm), and the corresponding steps on the headstock pulley are 17 & 3/8”, 14 & 5/16”, and 10 & 5/16” (441, 364 and 262mm) circumference respectively. This means the ratios are 22:63, 241:263 and 171:131 (which are very clunky, but correct – the greatest common factors of the pairs being 7, 1 and 2 respectively). Using very heavy rounding to get my head round it: 1:3, 3:2 and 2:3. With a motor speed fixed at 960rpm, that means the speed I can expect at the headstock are 335, 637 and 1257RPM -so basically I’ll be running the lathe on the fastest possible combination all the time. My workbench is just over 2’ (600mm) deep so there isn’t much space to waste, I’m reckoning on 11” (280mm) between the centres of the motor & headstock, which should mean the gaps between the two discrete parts of the lathe, plus them and the edges of the bench should be similar. This means the inside face of the belt needs to be 2’ 10 & 1/16” (865mm), 2’ 8 & 13/32” (823mm) or 2’ 10 & 15/32” (876mm) long, depending on which pulley step pair I want to use - which I think demonstrates that the two are not a matched pair. Knowing the length, I just had to decide on the type of belt. The options I found were: - Flat woven belt with “crocodile” joint; 32 GBP - Flat nylon/rubber multiply belt (apparently made as an endless loop); ditto - As above, but with a split requiring gluing; ditto - Polyurethane toothed belt (specifically a T10-880-25 but many other variations); 39 GBP - V belt e.g. B34 (was suggested to me but never really an option for me TBH); 6 GBP... … but what I actually went for was a longitudinally ribbed belt, specifically a 7PK880 … which is an alternator belt from a Renault Clio |

|

Please Log in to join the conversation. |

Boxford 4.5” x 17” Precision Plain Lathe 4 years 9 months ago #55989

|

|

|

Please Log in to join the conversation. |

Boxford 4.5” x 17” Precision Plain Lathe 4 years 9 months ago #55990

|

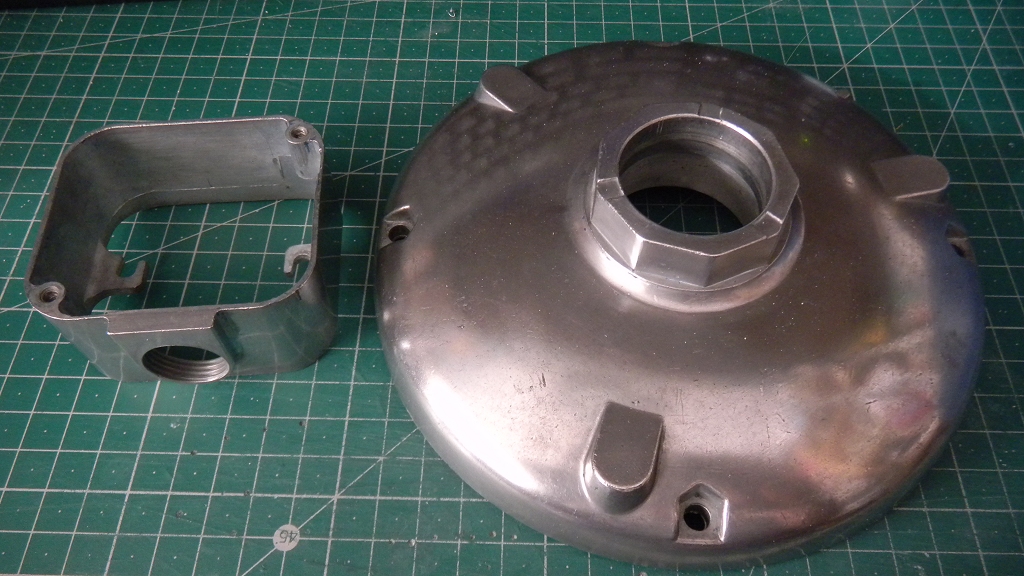

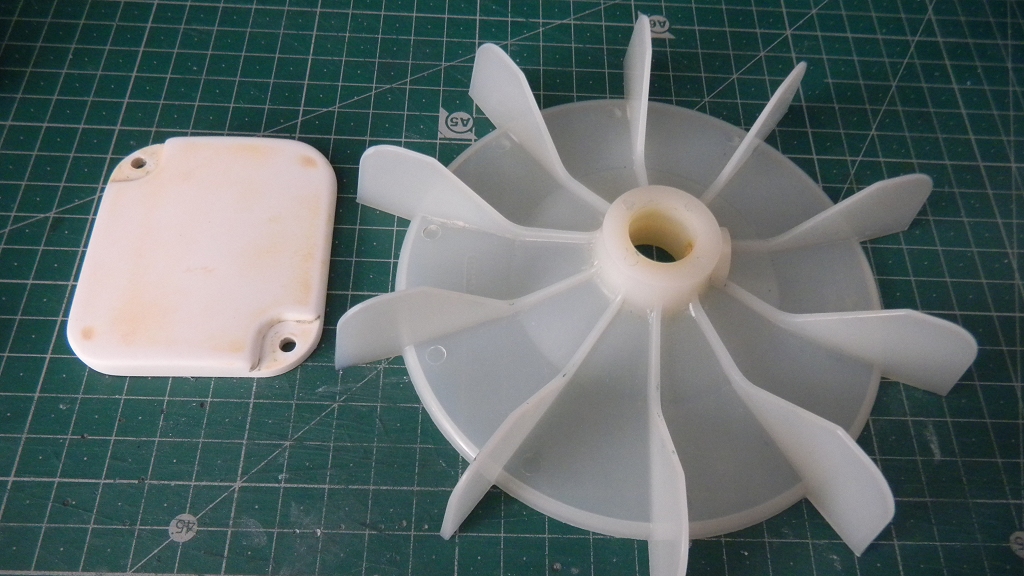

Fan housing had a lot of areas where the surface had turned to yellow powder anywhere where the paint had flaked off or where there wasn't any dirt... it had to come off but the surface is now very uneven...

Note matt finish after sanding & polishing ... that'll by polyethylene then (just like the Holiday Buggy) & need painting ... Speaking of which ... I didn't check the size of the Rustoleum sealer, at 125ml they turned out to be really poor value |

|

Please Log in to join the conversation. |

Boxford 4.5” x 17” Precision Plain Lathe 4 years 9 months ago #55997

|

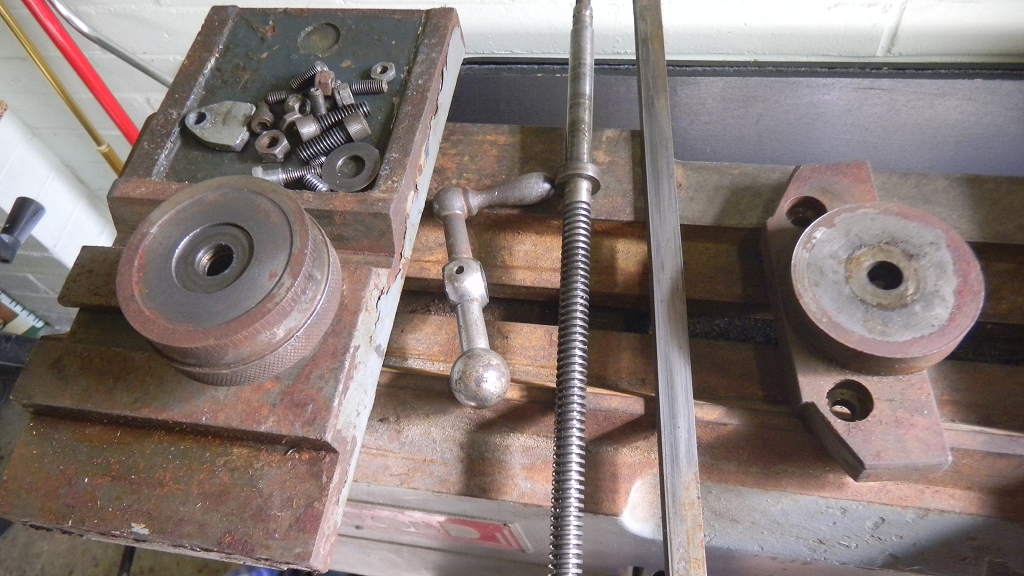

The smaller parts from the 1st batch of derusting are done, they came out black so I polished that off with Autosol, cleaned with WD40 then "finshed" with 3 in 1 oil:

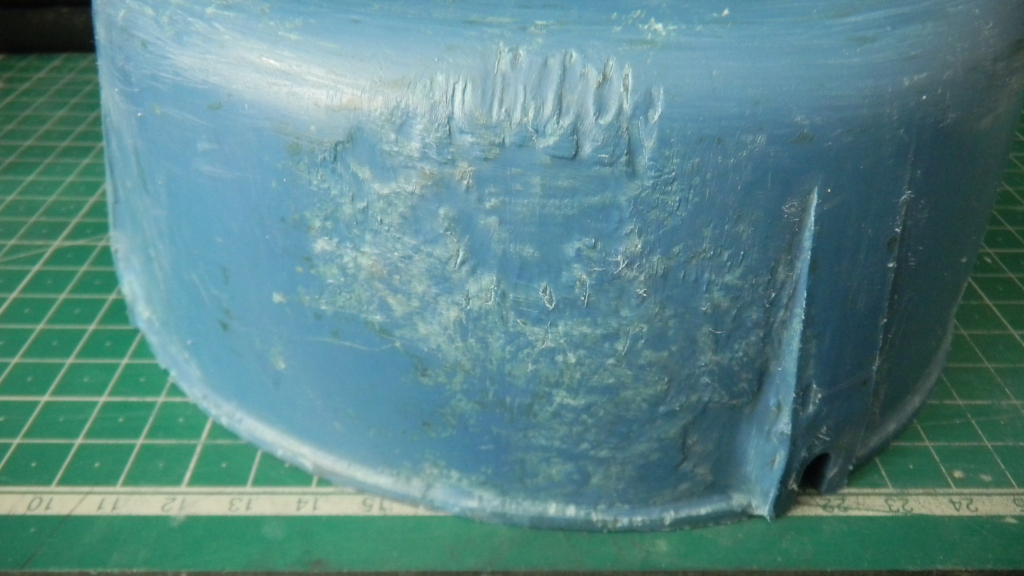

Heavier bits are still in the bath, I've since had a go at scraping & wire brushing the paint so the solution is even more disgusting now... Gel on the motor turned black so after wiping that off I gave it a second treatment - you can see the bare metal in places |

|

Please Log in to join the conversation. |

Boxford 4.5” x 17” Precision Plain Lathe 4 years 9 months ago #55998

|

Is it weird, but I love watching your posts restoring stuff.

I think it’s the fact you just don’t seem intimidated.

The following user(s) Liked this: Jonny Retro

|

|

|

Please Log in to join the conversation. |

Boxford 4.5” x 17” Precision Plain Lathe 4 years 9 months ago #56004

|

Hey Jonny,

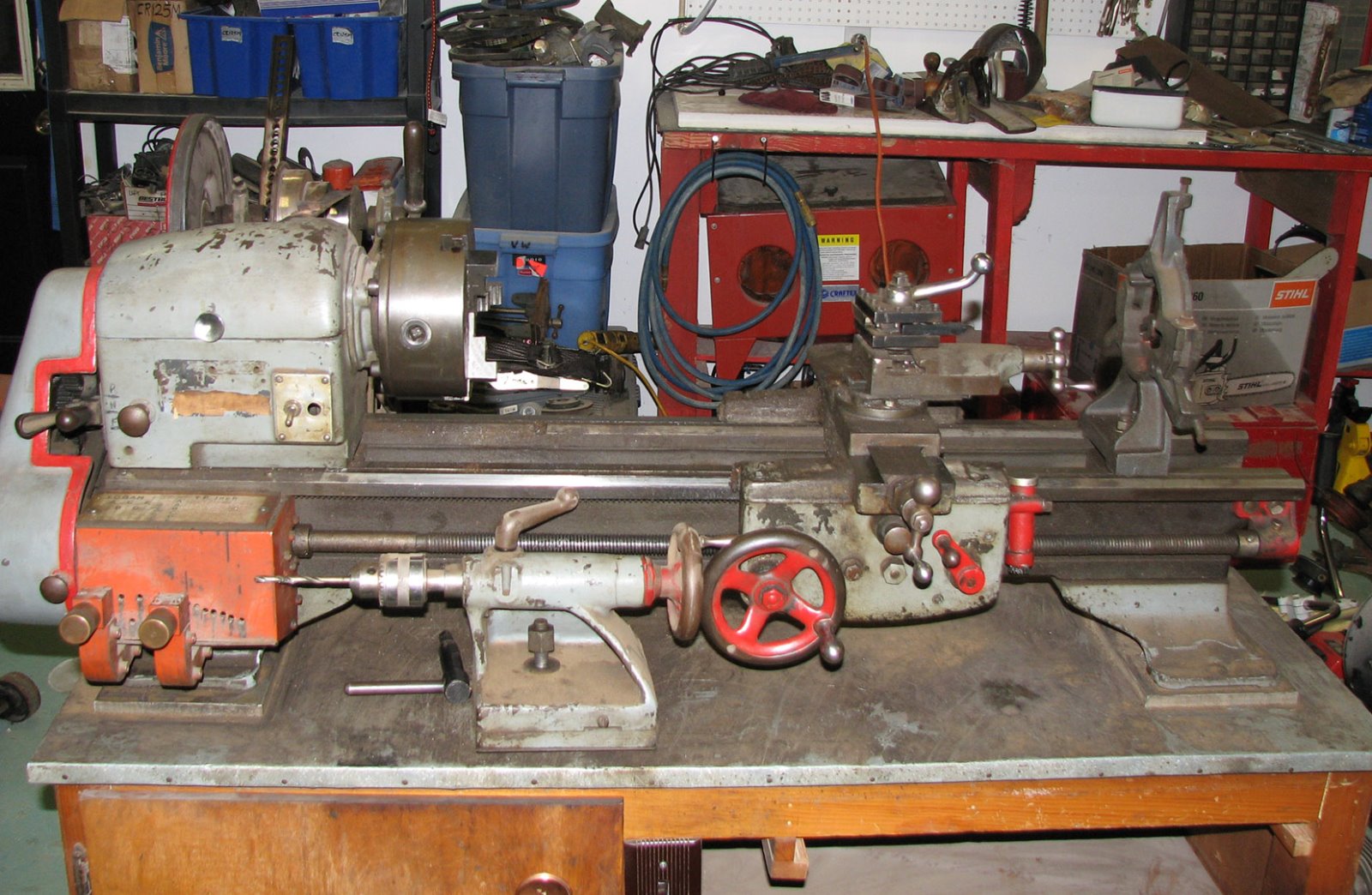

I have been following along a bit here and let me say I have never regretted getting a bigger lather up and running, first off its able to turn bigger things but the first time you turn a piece of steel in it....well its just a world of difference. Makes you wonder why you struggled with the unimat for so long. I am like you, I had a bit of training back in school but beyond that I mostly work like a sculptor, I know what I want and just remove everything that doesn't look like it...or something like that. I looked up the Boxford lathe on that Lathes.uk site and see the missing counter shaft assembly, but looks to have some fairly competent bodging to address that. Mine had the counter shaft but it had some questionable repairs and was set up almost completely wrong. I did source out a couple of used bits on ebay and made a new shaft and tensioner screw, it works great now but there were times when I wondered if I had made a mistake in buying it. About the belt, if you check my " after " picture you will see I am running a ribbed belt (or serpentine belt as they say over here) and it works excellent, mine came with a badly made leather belt so I needed something else an I am not sorry I made the switch. The modern ribbed belt should last a lifetime. You do need to disassemble the headstock to fit it but I am sure you were going to do that to check and or replace the bearings anyway, good choice you won't regret it. You will need some kind of tensioner, mine is sort of a turnbuckle affair with a lever to release it but I am sure you can do something with a hinge and a turnbuckle that will be just a effective. You might want to add a motor speed controller to slow it down a bit more too because of the missing counter shaft. I am sure you already have these things thought out but I just wanted to throw in my 2 cents again. It is always amazing how many things you can fix with a small lathe around, I can't count how many times I have been looking at a problem and suddenly realized...Hey, I can make a new one of those on the lathe!! Or if I just had something that would............ I went and checked back and my old post was Post 50715 if you want to search it but I stuck the pictures in here again, Much better looking with that new belt wouldn't you say......... After initial cleaning Almost done..... [/quote] From somewhere out in the wilds of central Ontario.

.......you build what you like, I will build what I like........it's all cool......

The following user(s) Liked this: Jonny Retro, stingray-63

|

|

|

Please Log in to join the conversation.

Last edit: by oldwilly.

|

Boxford 4.5” x 17” Precision Plain Lathe 4 years 9 months ago #56009

|

TBH I was hoping to get away without one & get the tension right by placing the motor legs in the right place & make use of the slots in the bottom of the motor mount for adjustment ... but that does seem a bit optimistic, especially now just typing it out. The Renault Clio tensioner would be the right size, already has decent bearings, and comes pre-fitted on a bracket with a curved slot at one end & a hook at the other ... I'm thinking that would give me two options - fixed tension, or a tension spring so it adjusts itself ... |

|

Please Log in to join the conversation. |

Boxford 4.5” x 17” Precision Plain Lathe 4 years 8 months ago #56025

|

Hey man,

That Clio tensioner idea is good, it really doesn't need too much tension but It is going to be excellent I am sure From somewhere out in the wilds of central Ontario.

.......you build what you like, I will build what I like........it's all cool...... |

|

|

Please Log in to join the conversation. |

Time to create page: 0.251 seconds