TOPIC:

Boxford 4.5” x 17” Precision Plain Lathe 4 years 8 months ago #56170

|

Finally starting on the lathe bed - this at least doesn't seem to have suffered any of the angle grinder vandalism found on the head & tail stocks ... here I've scraped off the loose stuff & back to bare metal around the badges, also got most of the rust off the top. Next step is masking & stripping the rest of the paint off, with some chemical help.

I'm sure the original colour was red, followed by light grey, dark grey (all well bonded) followed by light green (barely bonded at all) then light grey. |

|

Please Log in to join the conversation. |

Boxford 4.5” x 17” Precision Plain Lathe 4 years 8 months ago #56179

|

Can't take any credit for the bench, other than having the ability to click "Buy It Now" on eBay ... this arrived semi flat packed so all I've done is sealed it (the seven mini tins proved to be exactly what was needed (and not a brush stroke more) for 2 coats all over), assembled it & bought a 600mm x 1200mm sheet of aluminium for the top.

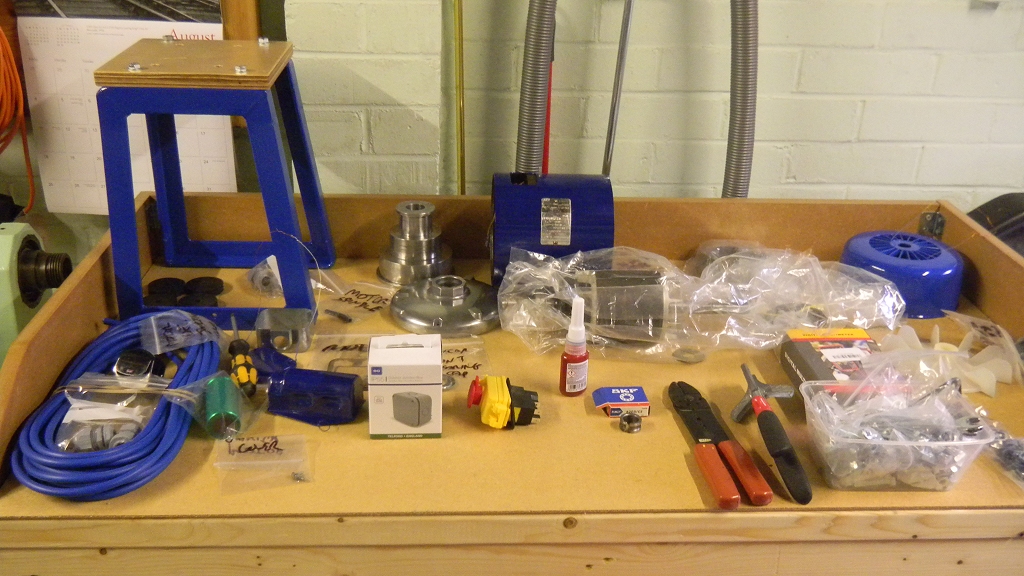

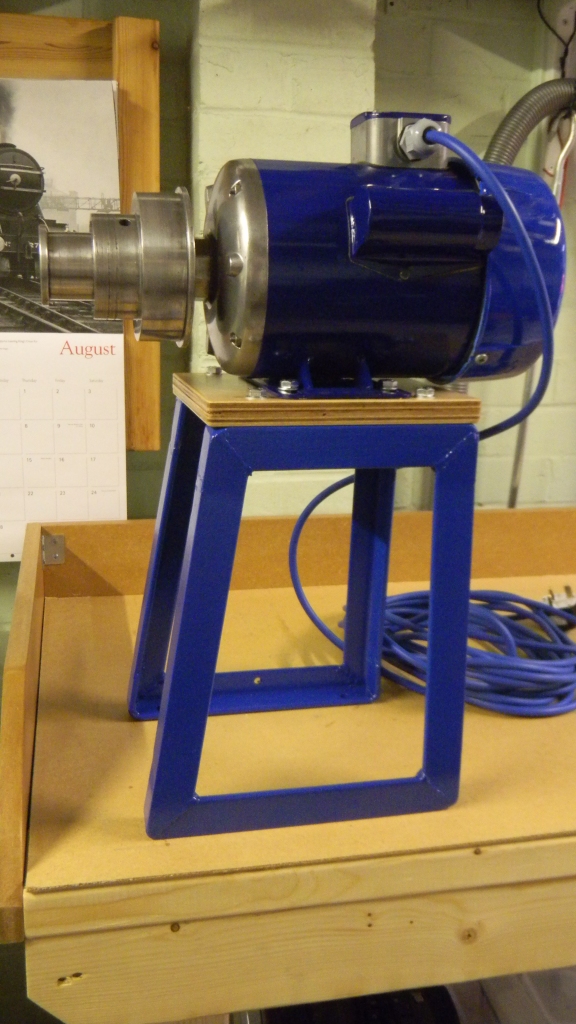

Almost everything I need to start rebuilding the motor: Bed feet join the pile of lighter than I'd have liked green ... |

|

Please Log in to join the conversation. |

Boxford 4.5” x 17” Precision Plain Lathe 4 years 8 months ago #56180

|

Paint stripping of the bed went very well, warm weather meant I could get all the spraying done too. Solar gain meant the big lump was still at 45C+ a couple of hours after being moved back into the garage

Apparently red & green should never be seen together, but I'm quite happy with the "Box-Ford" logo, even if the Art Deco styling would have been 30 years out of date when the lathe was made ... Supplier badge is still ok, but the masking removed the last of the red paint from the makers tag

The following user(s) Liked this: stingray-63

|

|

Please Log in to join the conversation. |

Boxford 4.5” x 17” Precision Plain Lathe 4 years 8 months ago #56181

|

I love these vintage plates.

|

|

Please Log in to join the conversation. |

Boxford 4.5” x 17” Precision Plain Lathe 4 years 8 months ago #56193

|

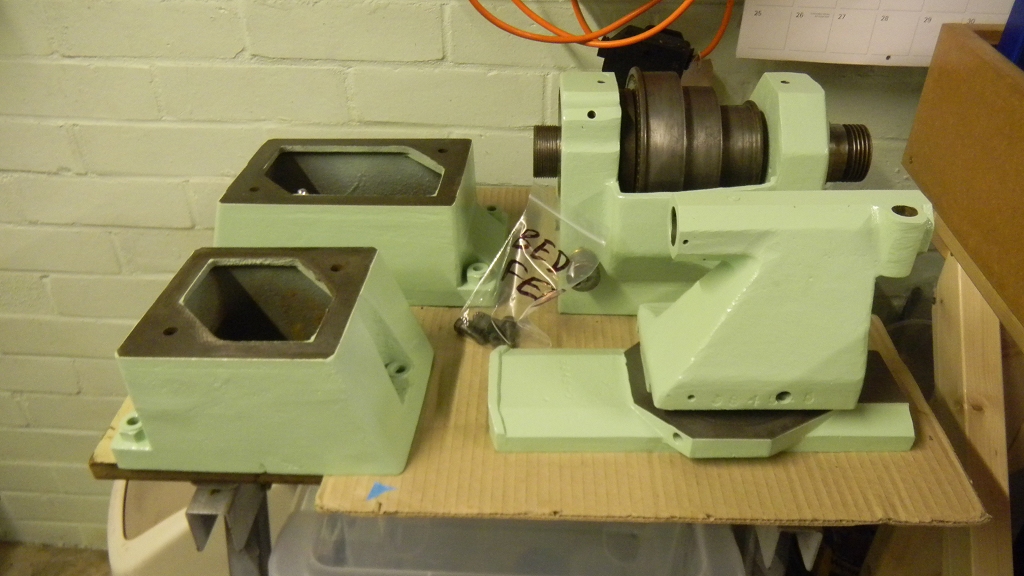

Intended to put the headstock & tailstock back together today & do a test fit ... test fit didn't work (and put chips in my nice new paint work

First pic shows two of the three key parts (other being a shaft with a cam section) needed for clamping - these are one of the two on the headstock, the tailstock has a single clamp which is very similar, but with a much shorter threaded section (& shorter overall length). Second pic shows where they need to be for initial fitting (with the cam at the lowest possible point too) to get it on to the lathe bed - note the complete absence of any possibilty of any thread engagement ... so I need to make three more (much larger than before) T-nuts on the Unimat if I want to go any further. Perfectly possible, but time consuming & tedious, not mention having to buy more material & another set of thread taps that I'll never use on anything else, and waiting for them to arrive On the plus side, motor is back together & running more quietly & smoother than before |

|

Please Log in to join the conversation. |

Boxford 4.5” x 17” Precision Plain Lathe 4 years 8 months ago #56287

|

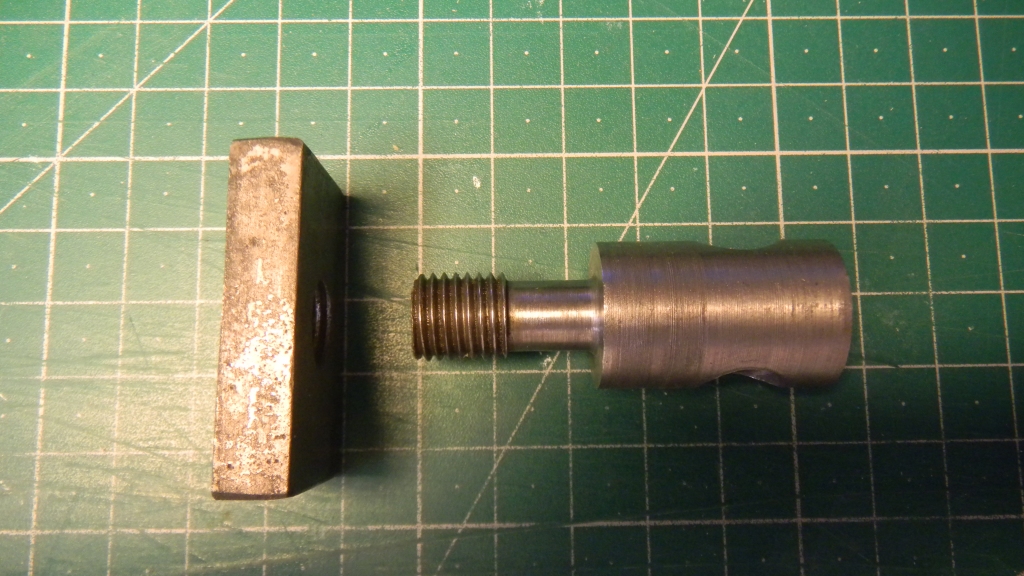

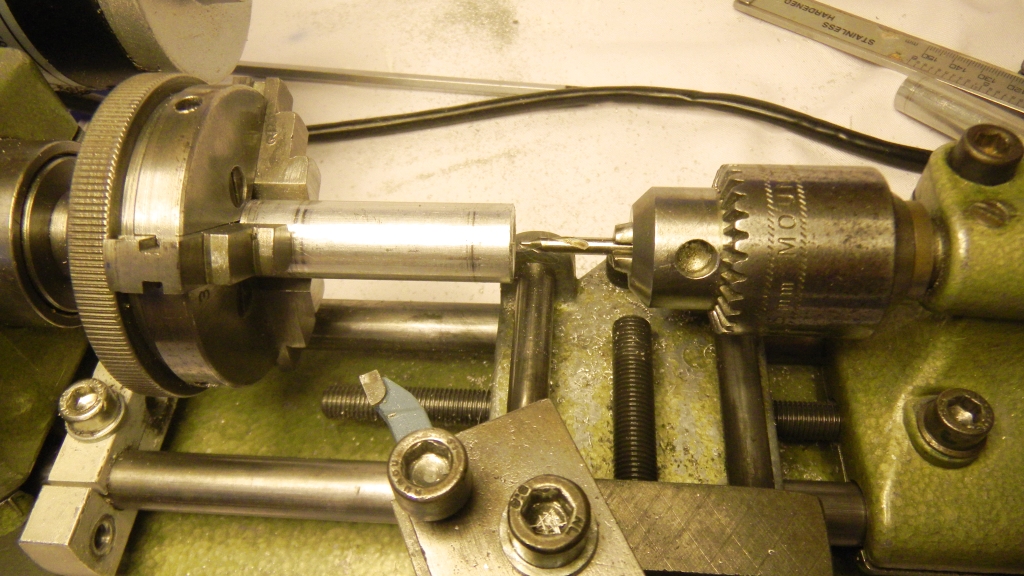

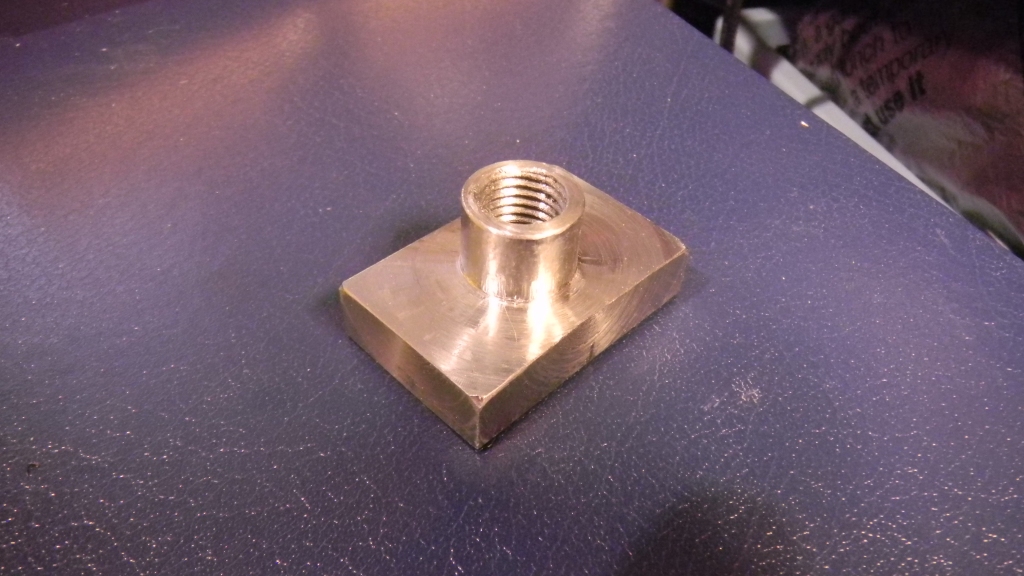

Working on the large T-Nuts ...

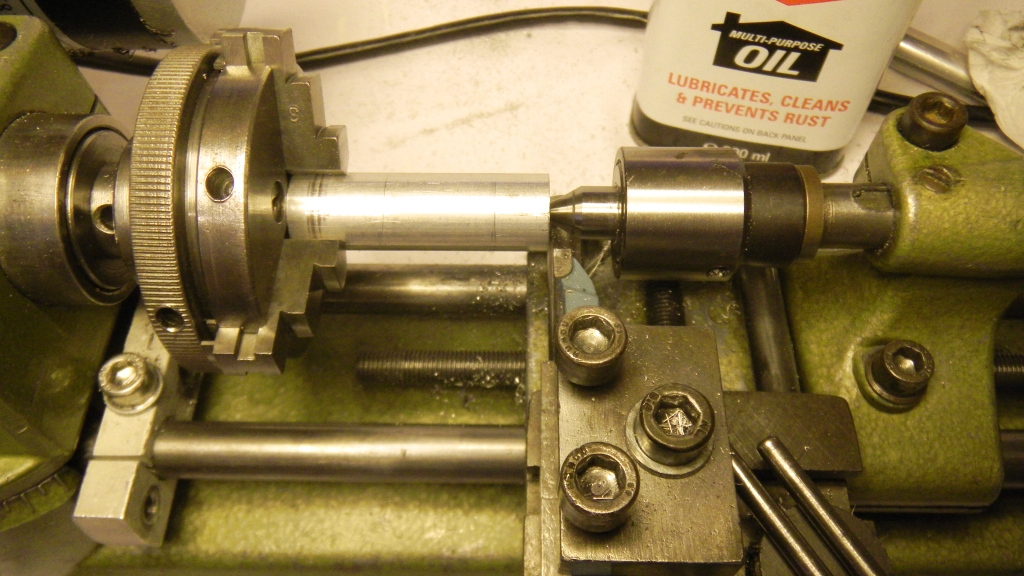

25mm x 25mm mild steel bar chopped to 38mm length, faced on all 4 sides, drilled to 9.7mm (being the starting size for 7/16" BSF taps): Unimat setup for facing ends "long" bit of 9/16" (14.29mm) Aluminium rod: Setup for drilling centres on shortened bit of Al. rod: Setup for turning one end down to size reqd for dog drive: ... |

|

Please Log in to join the conversation. |

Boxford 4.5” x 17” Precision Plain Lathe 4 years 8 months ago #56288

|

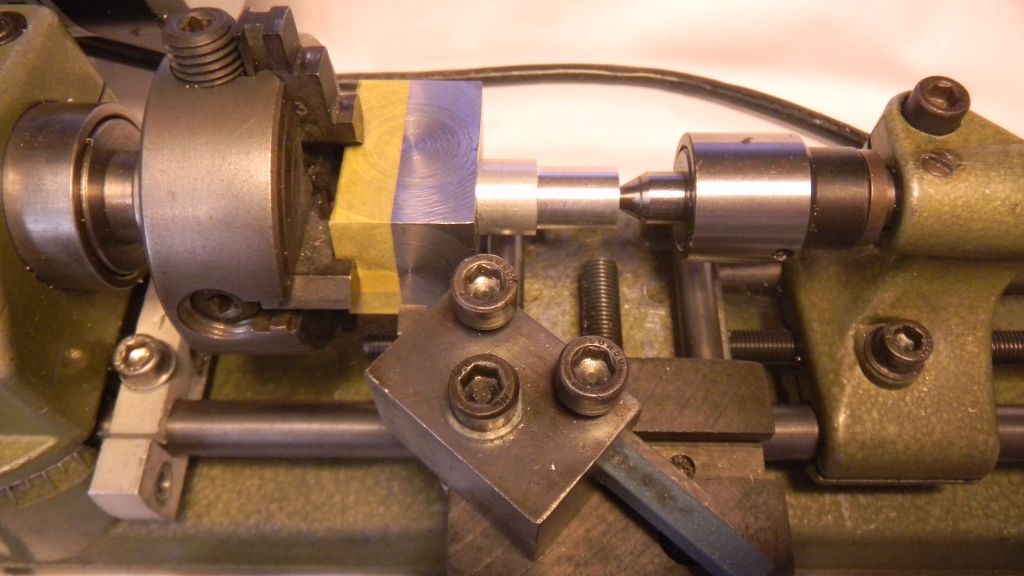

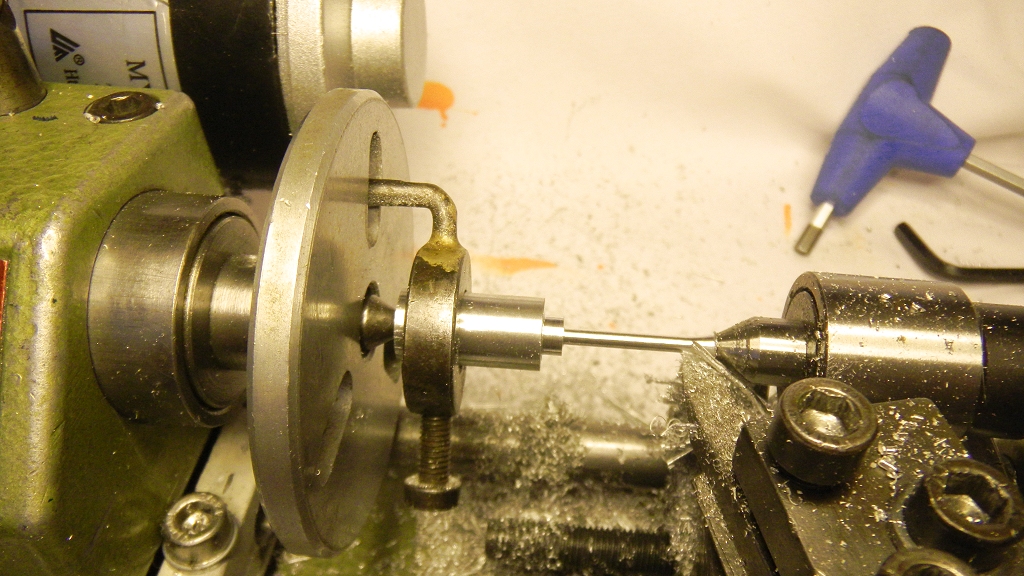

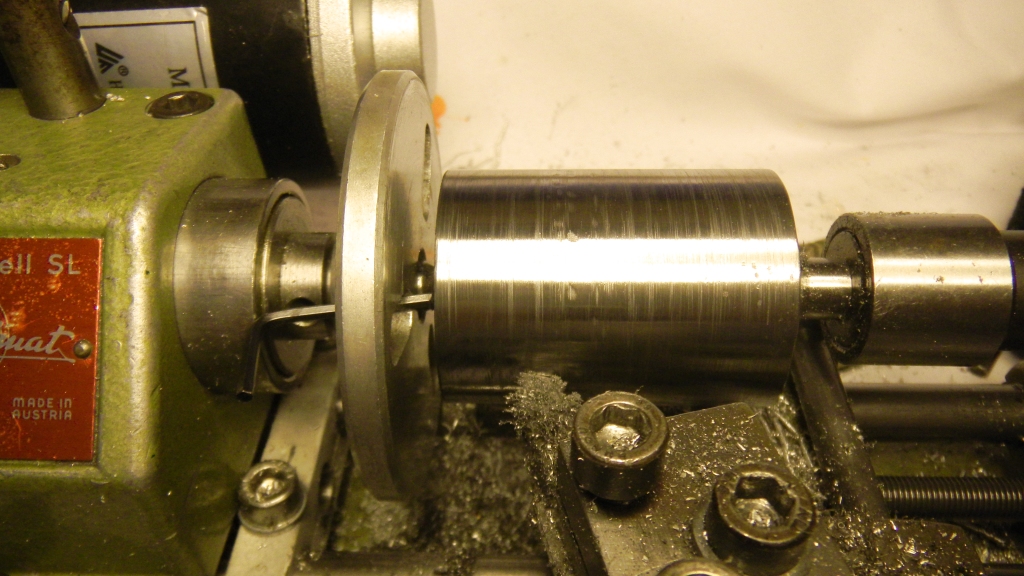

...

Setup for turning other end to size reqd. for support pin: Setup for turning vertical bit of T: Many passes later ... I stopped counting at 200+ & that wasn't even 1/2 way ... Vertical bit shortened to fit under head stock + threaded: I've already done a slightly longer one for the tailstock, I just have to do another one like the above for the headstock. I may get it done today (day six). Proving once again that while I can do stuff like this on the Unimat, I'd really rather not ... but on the other hand, If I didn't have it I don't know if I'd be able to do it at all |

|

Please Log in to join the conversation. |

Boxford 4.5” x 17” Precision Plain Lathe 4 years 8 months ago #56313

|

Got the nuts finished so got the headstock & belt on .... killed all the power to the house several times investigating why the motor (that was fine last time I tried it

Also wired in the on/off/emegenency off switch/box - once the lathe is sited more long term I may well fit another emergency stop (like a bar on the floor for foot operation), but for now a "hands free" one in the middle of the bench at the front (aka crotch operated) is the best place to have a single one. Unexpected costs on tools continue, I got most of the compound slide done but need 1/4" BSF (26tpi) taps & a die, plus a dial test indicator to go any further. The latter is to investigate just where the wobble in the centre of the 3 jaw chuck is coming from ... by eye the spindle is ok, but the backplate appears to be warped, and that gets passed on to the chuck & the results in eccentricity where the jaws meet. That will mean anything I turn on it will have a slight taper. It's not necessarily a big problem - it's very possible the backplate/chuck came off a different lathe and/or was never skimmed for this one, so it could just be that the backplate just needs a light skim of the back plate and/or refitting the chuck at one of the other two positions (it's held on by three screws) to resolve it. Giving the spindle nose and backplate thread another thorough cleaning showed they fit back together in exactly the same position, BTW. The DTI should tell me if the spindle is ok & give before & after runout figures for the skim. If the spindle is bent it's not entirely game over - it wouldn't be fixable, but I'll know what the runout is, and can work out what angle I have to set the compound slide to counteract the taper... I think. The markings on the dials behind the handwheels are marked in 1000ths of an inch - one full turn = 100/1000" or 2.54mm ... I'm sure I'll get used to it. I also discovered that the maximum the top section of the slide will move side to side is just under 5" (125mm) - and as there's no rack or lead/feed screw, that's the longest possible cut it will be possible to do without introducing some sort of step in the finish from moving the compound slide as a whole. It'll take longer components - but the length of cut is very limited. That feels like quite a limitation, but so far I can't think of anything on my to do list that will be compromised...

The following user(s) Liked this: larbut

|

|

Please Log in to join the conversation. |

Boxford 4.5” x 17” Precision Plain Lathe 4 years 7 months ago #56316

|

I've always been fascinated by lathes, but at the same time think using them is like magic.

I've used a wood lathe, so I get the principle, what looks like magic to me is the considerations you have (?) to do regarding metal types, support, tools, etc. Like the above post where you show the required steps to make the T-nut... magic... Signature now gets correct formatting if you edit it in your Profile. Use normal BBcode if you want.

www.tamiyabase.com was formatted automatically. |

|

|

Please Log in to join the conversation.

Last edit: by larbut.

|

Boxford 4.5” x 17” Precision Plain Lathe 4 years 7 months ago #56323

|

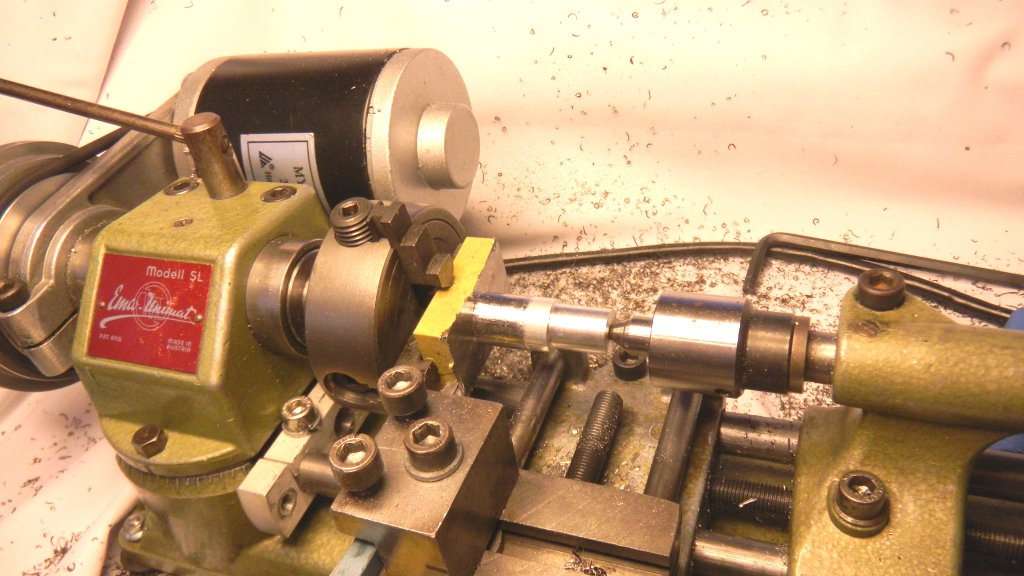

TBH I should have got a fixed steady for the Unimat SL a long time ago ... and been more willing to use centre drills, and the faceplate & dog drive ... If I've improved at all it's due to a combination of "having" to do more involved lathe work, and reading up on the subject ... I have a big pile of paperbacks to get through, plus more in the post - this is what I've read on the subject in the last couple of weeks: "Using The Small Lathe" (L.C. Mason, MAP, 1963) - a bit dry, not enough photos, starts with adding mass to a food operated treadle flywheel using shutterring and concrete ... "The Beginner's Guide to the Lathe" (P.Marshall, reprint of 1987 reprint of 1924 revised edition) - not recommended as a first read, the terminology has changed, as well as basic equipment ... "Basic Lathework" (Stan Bray, SIMB WSP #45, revised edition 2013) - tries to do everything in one volume & consequently covers areas I wasn't interested in & was a bit light on thing I was, but a very good overview anyway ... "The Compact Lathe" (Stan Bray, Argus 1990, 2012 reprint by SIMB) - read this some years ago & TBH didn't get a whole lot out of it then, recently re-read & did get a bit more. text & photos are completely different from the above despite the same author theoretically covering the same ground... "Unimat Lathe Projects" (Gerald Wingrove, New Cavendish Books 1979) - Covers some basics then rapidly moves into making 10 tools to suit the Unimat 3 ... maybe it's a badword of a lot stiffer than the SL when set up as a drill or mill & a lot less faff to swap between the lathe/mill/drill/chop saw states, but I don't think I'd want to try most or even all of it on such a tiddly machine (or even 4 of them) ... "The Mini-Lathe" (David Fenner, Special Interest Model Books Workshop Practic Series #43, 2008) - focusses on the generic 7x14" Chinese Mini Lathe & making one work properly, I'm only halfway through it but it does seem to be moving on to making useful stuff (for that lathe) but ideas/techniques are probably transferable ... Despite all the theory, sometimes a bit of bodgery is required. Take this for example ... This is the eccentric adjuster centre from the Boxford's toolpost - it refitted ok, but really needed to be a light sliding fit to taken advantage of the possibilities (I think) of being off centre, and certainly needs it for the tool height adjustment to work, but decades of use plus more of rusting meant it just wasn't moving. I needed to skim it, theory says you need to support one end of the work in a steady - but if you do that, you can't access even one half in one go - and even then, you shouldn't use a chuck to hold it as you would 1/ need to swap ends and 2/ take a bit off & try it, then repeat ... and you'll never get the alignment the same as the first time, so there'll be some sort of step. The "answer" I came up with was to use a centre drill to make a small whole in each end (which is I suppose vandalism) & use the dog drive between centres ... but the only way to drive it was to make a pin to fit the hole in the adjuster, with one end small enough to fit the Unimat faceplate... After all that thought & some turning, my new tooling didn't fit. If you're thinking the last picture doesn't look very safe, I can assure you that the Allen key only shifted after the Blu Tac flew off when I turned the Lathe off after the skim... I guess what I should have done was drill the faceplate & fit a pin (more vandalism?) ... ps typing this up took longer than it did to to the work yesterday evening, I've done nothing today & doubt if I will tomorrow either... |

|

Please Log in to join the conversation. |

Time to create page: 0.146 seconds