|

|

|

TOPIC:

Blakbird's 58518 Super Clod Buster Build 5 years 7 months ago #51703

|

Note: This build log is excerpted from my

web site

. You can check there for larger versions of every photo or further reading.

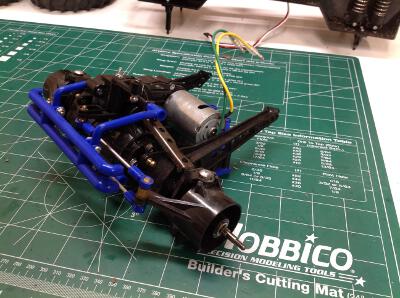

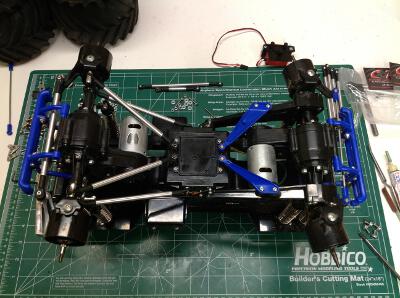

The original Clod Buster came out in September of 1987 as 58065 and was really the first of its kind. This was a real scale monster truck with solid axles, four wheel drive, four wheel steering, giant tires, 8 huge shocks, and a scale body that looks an awful lot like a 1983 Chevy truck (the body was originally a licensed Chevy, but no longer uses the logo in the latest incarnation). It uses a single chassis mounted servo for 4WS and the power system is a pair of 540 sized motors mounted directly to the axles. By modern standards , this is not a great truck. The steering is pretty terrible, it is not fast, it does not have independent suspension, and it does not have oil dampers. But if you remember what this is, a scale monster truck, it actually does its job very well. It looks great and it bounces around like crazy. The original Clod was produced for a long time and many aftermarket parts were made for it. In 1990 they came out with the 58089 Bullhead which is exactly the same truck with a different body. It took until the 58321 Super Clod Buster in 2004 to get any updates, and from what I can tell it is just the same truck with an electronic speed control. The Super Clod was released again in 2013 as 58518 and that's the version I have. I replaced the stock friction dampers with oil shocks. I kept the stock silver can motors and ESC, using an Arrma 15Kg servo for steering. I eventually added some LEDs when I standardized on my rule that all hard body vehicles should have lights. The biggest "upgrade" is my addition of aluminum beadlock wheels which caused all kinds of problems as you can read about below. I later made rather extensive modifications to the suspension in an effort to improve the steering. I was only partially successful. Finally I decided that if I couldn't make it perform great then I could at least make it look cool so starting doing some aesthetic upgrades. There is now a driver figure which you can see through clear windows, and I added a moving supercharged V-8 instead of the static blower that came with the kit. The Clod Buster has a LOT of hardware and it is really heavy. The first photo shows an assortment of some of it. There are actually a fairly small number of types of screws making it easy to find what you are looking for. The build starts off immediately with the electronics and the steering servo comes first. Although this model has 4 wheel steering, it only uses a single chassis mounted servo. For this reason you need to use one with plenty of torque. This is an ARRMA 15 kg (208 oz-in) waterproof servo with metal gears. Even with all the torque, the steering isn't very good because most of the torque is lost in the servo savers on the axles. The main chassis tub is all one piece but it is reinforced and stiffened with a few metal inserts where the suspension links attach. The steering rods run along the length of the body in either direction. There is no central gearbox or transfer case in the Clod. Since the motors are mounted on the axles, the gearboxes must also be on the axles. You build two identical powered axles, and each contains an integral gear differential. The gears are HUGE! You will not be stripping any of these gears any time soon. The differentials cannot be locked, but you can make them tighter with some anti-wear grease. The front and rear axles are no longer quite the same. They both use the same bumper and suspension links, but the servo savers are assembled a little differently. Because both steering rods are on the same side of the chassis but one of the axles is installed backwards, you need to build the servo saver with the crank facing the other way. I also adjusted the position of the ball stud so that the rear steering would have less travel than the front. The suspension links are a bit unusual because they are not just rods but actual profiles. The blue lower links are a soft flexible plastic and must actually bend because they mount in 3 places. The black links connect to a ball joint on the side of the chassis. All of the rod ends are a really tight fit on the balls so it is not easy to remove them to make adjustments. Try to get it right the first time. I did not follow this advice. The completed chassis. The shocks are "friction damper" type which means they have no oil. In fact, they have no damping either. These are as simple as shocks can get, just rods in a can. In practice, the tires are so bouncy that the shocks probably don't do much. Despite the long length of the shocks, they also have very little travel. This is just as well because the servo saver bottoms out on the chassis tub quite easily. The battery is mounted in a slot accessed from the side of the chassis. I really like this because it means you don't have to remove the body to change the battery. I used a Tamiya TEU-106BK speed controller which can control two parallel bushed motors. You only need a two channel radio since the four wheel steering uses one servo. |

|

|

Please Log in to join the conversation.

Last edit: by blakbird.

|

Blakbird's 58518 Super Clod Buster Build 5 years 7 months ago #51704

|

Let's get something out of the way right from the start. The Clod Buster is not a high performance truck. Adding high performance parts to it pretty much just makes it worse. This is an old design truck made for bouncing around the lawn, and it does that job just fine. The upgrades I made were mostly just for fun, and in most cases I had to make additional mods just to restore the original performance.

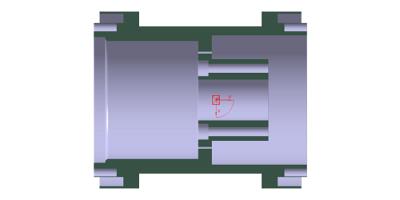

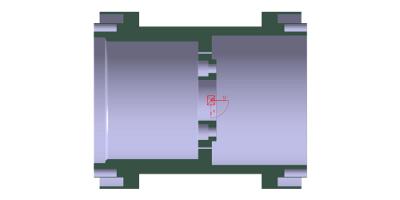

The friction dampers are adequate for this truck, but it still bothers me to have "shocks" which are so low-tech. I happened to have 8 extra oil shocks from my TXT-2 because I upgraded that truck to aluminum shocks. They are not quite the same length, but if you put the longer rod ends on the oil shocks they are pretty close. I can't claim to have actually noticed any performance difference after installing these shocks, but they do make me feel better somehow. RC4WD offers aluminum beadlock wheels for the Clod Buster, and I thought they were so cool that I ordered them before even building the model. You also need an adapter to fit the hex size of your particular model, in this case that's 12mm. In the pictures you can see the stock plastic wheel compared to the aluminum wheel, front and back. In the first photo you can also see the white mold release agent that was present on the tires out of the box. It took me a lot of scrubbing with my official Tamiya brush to get them to look smooth and clean on the right. As cool as these new wheels are, they are a big problem. First of all, the Clod Buster steering system is terrible right out of the box. All of the servo force is lost in the servo saver, and the steering geometry is all wrong. The Ackerman angle is backwards and so is the caster. The result is that the front wheels basically don't steer at all and the back wheels steer a lot so it drives like a forklift. The aluminum wheels do not have the same offset as the stock wheels which results in the track width increasing by almost two inches. While this might be good for stability, it makes the steering completely unusable and it doesn't look right either. To solve the problem, I decided to modify the wheels to decrease the offset. The pictures below show the CAD model I made of the wheels. On the left is the aluminum wheel as it comes from RC4WD. Once the adapter is on, the mounting face is essentially flush with the edge of the wheel. I wanted to the mount to be deep inside the wheel, so I decided to remove 23mm of aluminum which I accomplished on a friend's mill. This is a pretty major modification and I screwed up some of the dimensions despite all my preparations which required that I build a spacer to install the final wheels, but in the end it worked. The difference is incredible. It drives so much better now. Note that I also replaced the servo horn with a much longer version to give the steering rods more travel and tightened the servo savers almost to the stops. There are aftermarket companies which offer conversions to move the steering servo to the axles, but I didn't want to do this since it ruins the scale appearance. For reference, I did try swapping the wheels and tires with the TXT-2. This worked OK for the Clod Buster, but the TXT-2 couldn't handle the heavy aluminum wheels either so I switched back. |

|

|

Please Log in to join the conversation. |

Blakbird's 58518 Super Clod Buster Build 5 years 7 months ago #51705

|

One year later....

Those aluminum wheels and oil shocks were nice, but I was always unhappy with the performance of the Clod. Part of it was all the extra weight I added, but in particular the steering was just terrible. I resisted any kind of servo-on-axle steering because I wanted it to stay a Clod, but I finally found some parts at CPE (Crawford Performance Engineering) that I thought kept it close enough to stock while addressing some of the more serious issues. The picture below just looks like a pile of links, but there is a lot more going on here. This step took me several hours. I tore off the original plastic suspension links and replaced them with a real 4-link suspension. I also replaced the steering tie rod and servo link with much stronger versions. But most importantly I replaced the mushy servo saver with an aluminum version. This system has no springs. Rather it is a solid connection, but it is only kept solid with friction so it can slip if enough pressure is applied. It needs to be quite tight to steer these heavy wheels. You can also see the new shock mounts which are quite a bit higher than the old versions which were connected to the lower link. This give some welcome extra clearance to the servo links. Here we can see the new system installed on the front with the old system on the back. The difference is substantial. The original suspension is not a true 4-link because the lower links are not independent. Instead they attach to the middle of the upper links and provide lateral support. The new system is a real 4-link which allows more motion. The right hand image shows all the replaced parts.

The following user(s) Liked this: stingray-63

|

|

|

Please Log in to join the conversation. |

Blakbird's 58518 Super Clod Buster Build 5 years 7 months ago #51708

That's the bracket that connects the motor mount to the link? I actually did not have any problem with it, but it no longer even exists now that I switched to 4-link suspension. It probably won't break in my parts bin. |

|

|

Please Log in to join the conversation. |

Blakbird's 58518 Super Clod Buster Build 5 years 7 months ago #51710

|

Mine have never brocken. And I used it as I was young .... no limit...

|

|

Please Log in to join the conversation. |

Blakbird's 58518 Super Clod Buster Build 5 years 7 months ago #51711

|

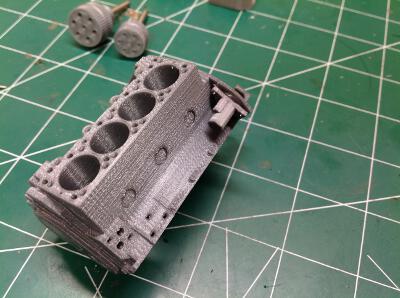

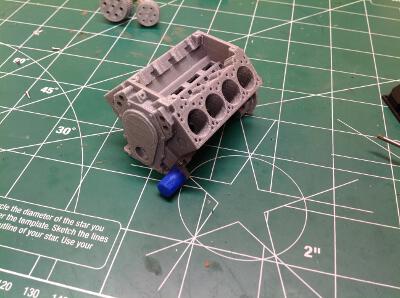

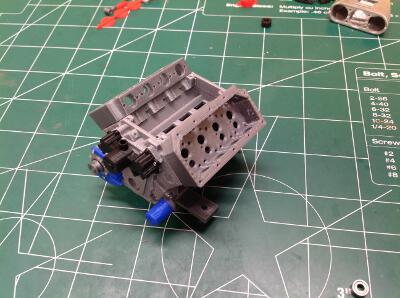

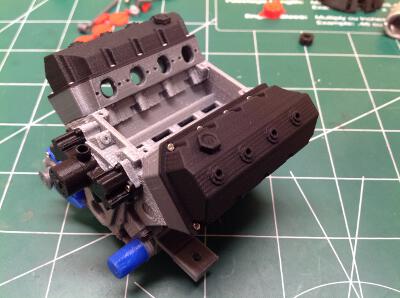

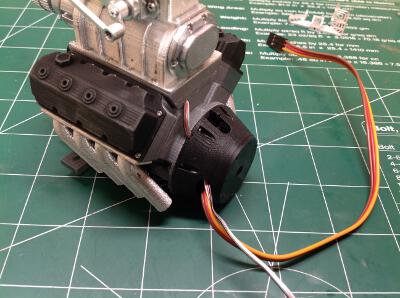

Next up is a 3D printed supercharged V-8. I bought this a while ago off of eBay because it was so cool and had been trying to find a home for it. The Clod Buster already has a fake blower sticking out of the hood and plenty of room in the front of the chassis so it seemed like a good home. I can't believe how much cool stuff comes in this kit. Dozens of 3D printed parts, a bag of hardware, and 2 servos. Everything you need to built a (fake) working V8.

First step is to attach the starter to the block. Yes, this thing is detailed enough to have a starter. Next step is the oil pump and filter. Note that the cylinder bores are purely ornamental; nothing will go into them. There are no pistons. Now I attach the water pump to the front of the block followed by the alternator and its support bracket. There is no timing chain. Next up is the heads and then the valve covers. This is certainly starting to look like an engine. |

|

|

Please Log in to join the conversation. |

Blakbird's 58518 Super Clod Buster Build 5 years 7 months ago #51712

|

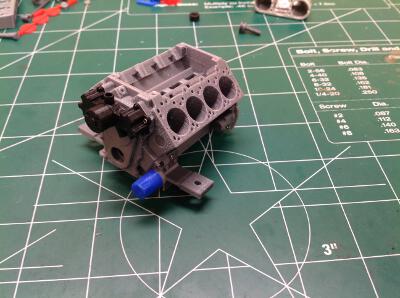

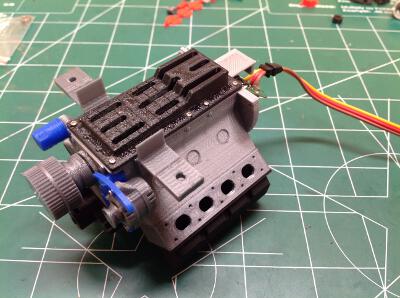

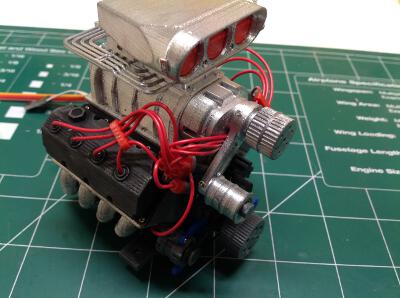

Now we'll start to put some electronics inside. At first I thought this was a supercharger impeller, but it is actually a little fan to cool the motor. The motor is extracted from a full size servo. The potentiometer is used to set the idle speed by telling the servo it is a little bit off center. The throttle can then be used to rev up to full speed. A very clever solution. The 4-sided control horn from the micro servo is re-used as a connector for the fan and then pushes onto the gear of the servo motor.

From the bottom you can see how the servo motor directly drives the lower pulley which would be the crankshaft connection. We then add some motor mounts and an oil pan which is slotted to allow cooling the motor. Servo motors are not really designed to run continually, and I don't know how this one is going to hold up. Here's the air intake for the supercharger. The butterfly valves can pivot to open and close. A micro servo (here painted chrome) is installed on the bottom with a small servo horn protruding. A tiny arm connects the servo horn to the butterfly valve which allows it to open and close. At idle it will be closed and it will flare open as a function of throttle position. The upper drive pulley has also been installed to the intake manifold.

The following user(s) Liked this: stingray-63

|

|

|

Please Log in to join the conversation. |

Blakbird's 58518 Super Clod Buster Build 5 years 7 months ago #51713

|

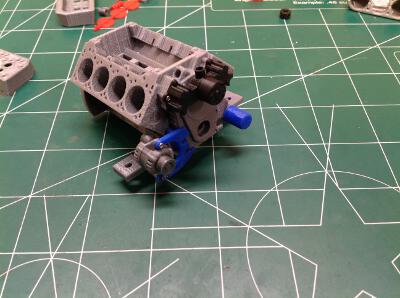

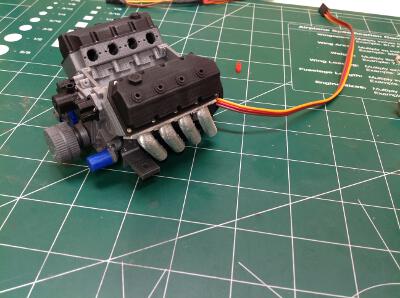

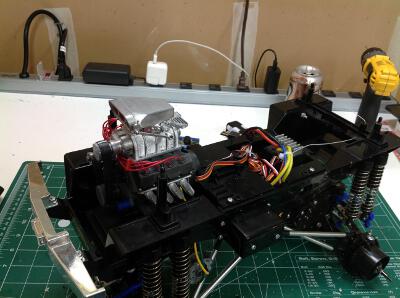

Now the exhaust manifolds have been installed. There are several styles available. I chose these because I didn't want to cut so big a hole in the hood to allow vertical pipes. In the right hand image the intake is installed.

From the back of the engine you can see where the pot sits and how the PCB is tucked away. Once the bell housing is installed all of this is hidden but you can still access the pot to control the idle speed. Now the fiddly bits: the spark plug wires. I actually found installing these kind of relaxing. The instructional video made it all quite clear, and I love how neat they look once the wire looms are installed. The image doesn't show the alternator belt or supercharger belt, but you can see them in the following image. To install in the Clod I had to do some thinking. I cut the cross brace between the shock supports and attached the engine using tall standoffs from below. I added another small support in the rear so it wouldn't wobble since this truck is quite bouncy. Here's the truck before and after the update. The old blower just sat on top of the hood in a small recess. I had to cut a large irregular hole to make room for the new engine, but it looks great. So far I've found that the system draws a lot of power and keeps cutting out even after I added a BEC. I probably have too much friction somewhere so it deserves a close look. |

|

|

Please Log in to join the conversation. |

|

|

|

Time to create page: 0.253 seconds