TOPIC:

8x4 MAZ/MA3 535A from Lunchkins 4 years 9 months ago #55701

|

The following user(s) Liked this: stingray-63

|

|

Please Log in to join the conversation. |

8x4 MAZ/MA3 535A from Lunchkins 4 years 9 months ago #55709

|

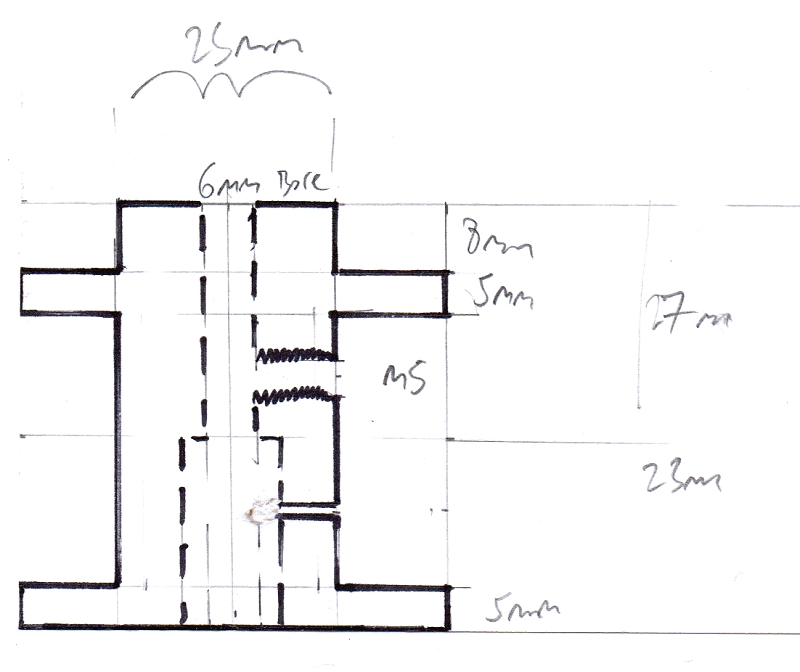

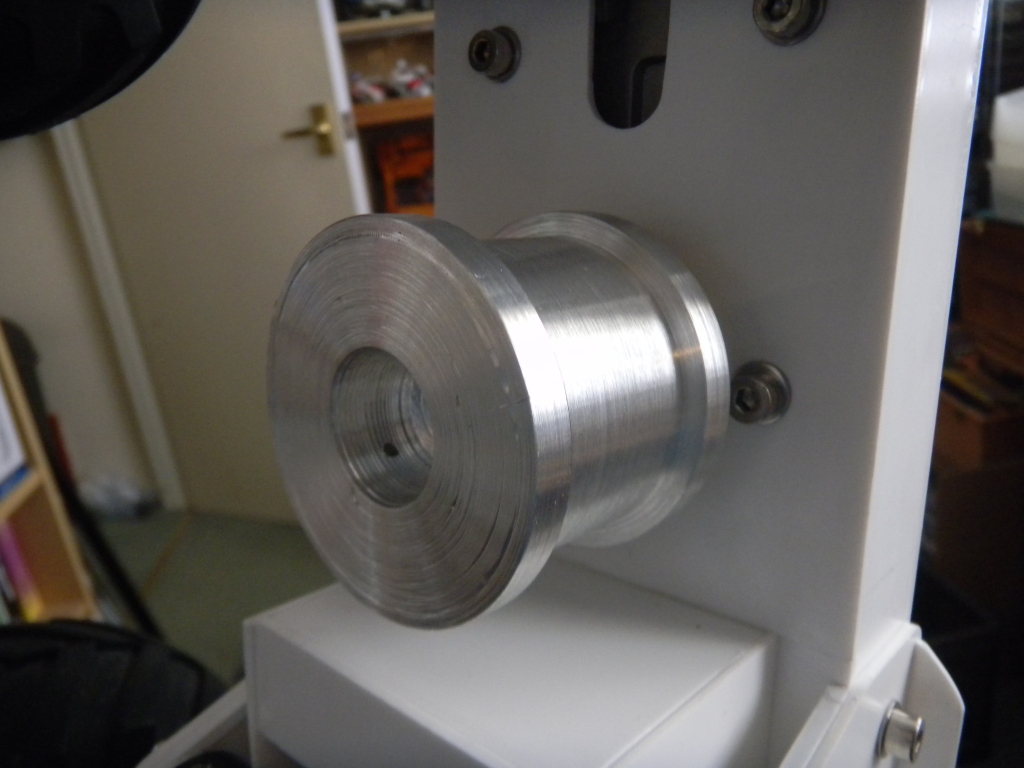

Thinking about the cable reel, 50mm diameter is about as big as I can get on the Unimat, and as I don't fancy hand sawing a bar that big I was limited to precut 50mm or 100mm lengths (I couldn't really justify buying a bigger 7x14" lathe and/or bandsaw for just this one piece).

I've come up with a back-of-a-cigarette-packet design (neither particularly square or symetrical I found a hose drum capacity calculator at www.copely.com/...alculator/ , and plugging in values from my sketch (d = 1.5mm, core = 26, flange = 50, traverse = 32) suggested I'd get 20 to 23 _metres_ of "hose" on my reel. This seemed a lot, so I wanted to check the maths... flange - core = 14mm, / 1.5mm = 9 layers traverse of 30mm / 1.5mm = 20 rounds per layer core circumference = pi * d, and will go up 3mm per layer d c

layer 1 3.142 26 81.692 20 1633.84

2 3.142 29 91.118 20 1822.36

3 3.142 32 100.544 20 2010.88

4 3.142 35 109.97 20 2199.4

5 3.142 38 119.396 20 2387.92

6 3.142 41 128.822 20 2576.44

7 3.142 44 138.248 20 2764.96

8 3.142 47 147.674 20 2953.48

9 3.142 50 157.1 20 3142

sum 21491.28 mm... or 21.49m. I just have to make it now ...

The following user(s) Liked this: stingray-63

|

|

Please Log in to join the conversation.

Last edit: by Jonny Retro. Reason: typos

|

8x4 MAZ/MA3 535A from Lunchkins 4 years 9 months ago #55725

|

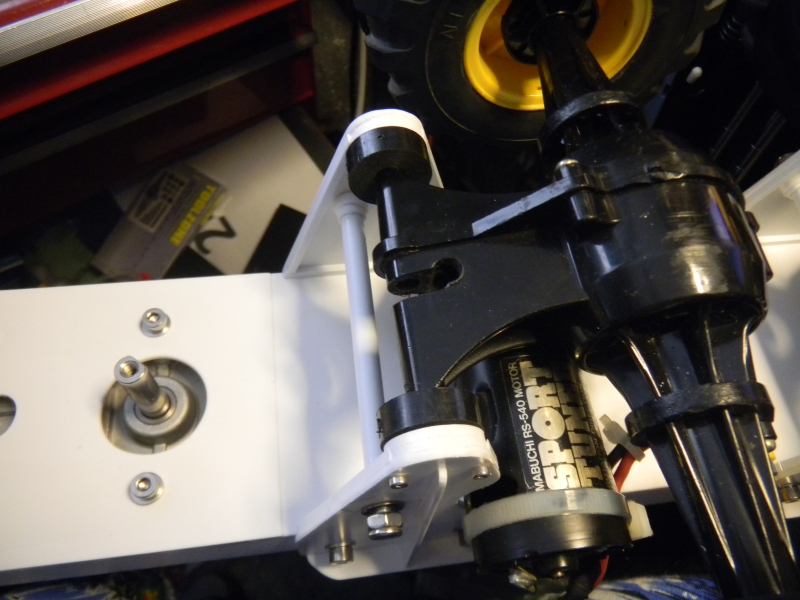

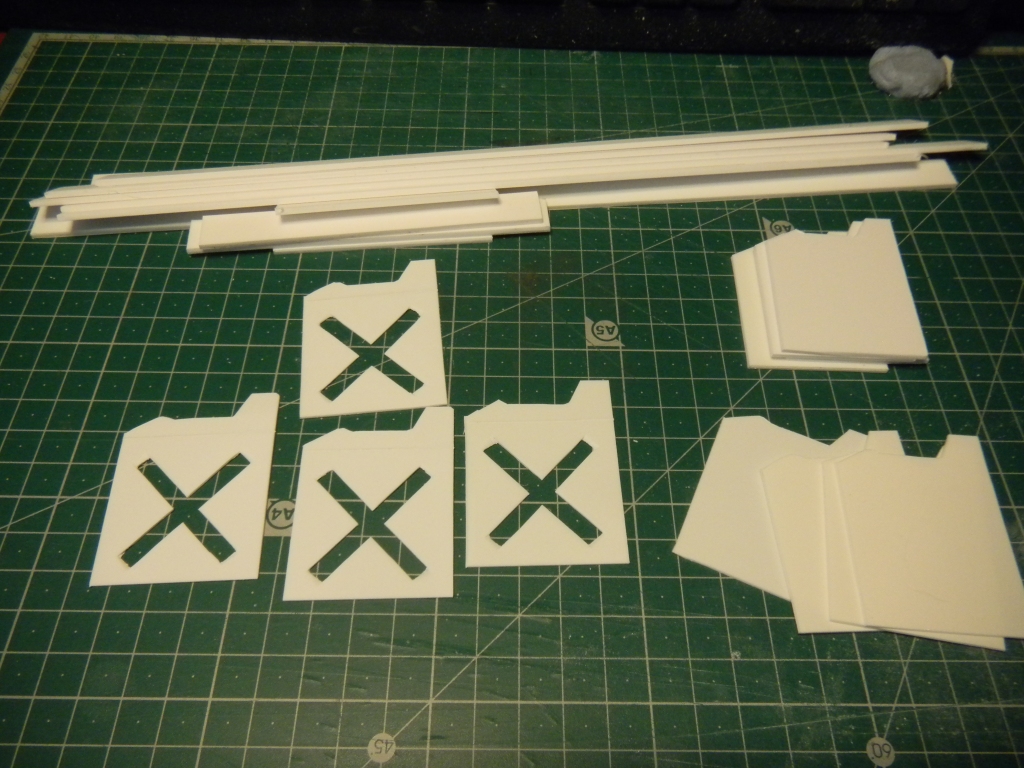

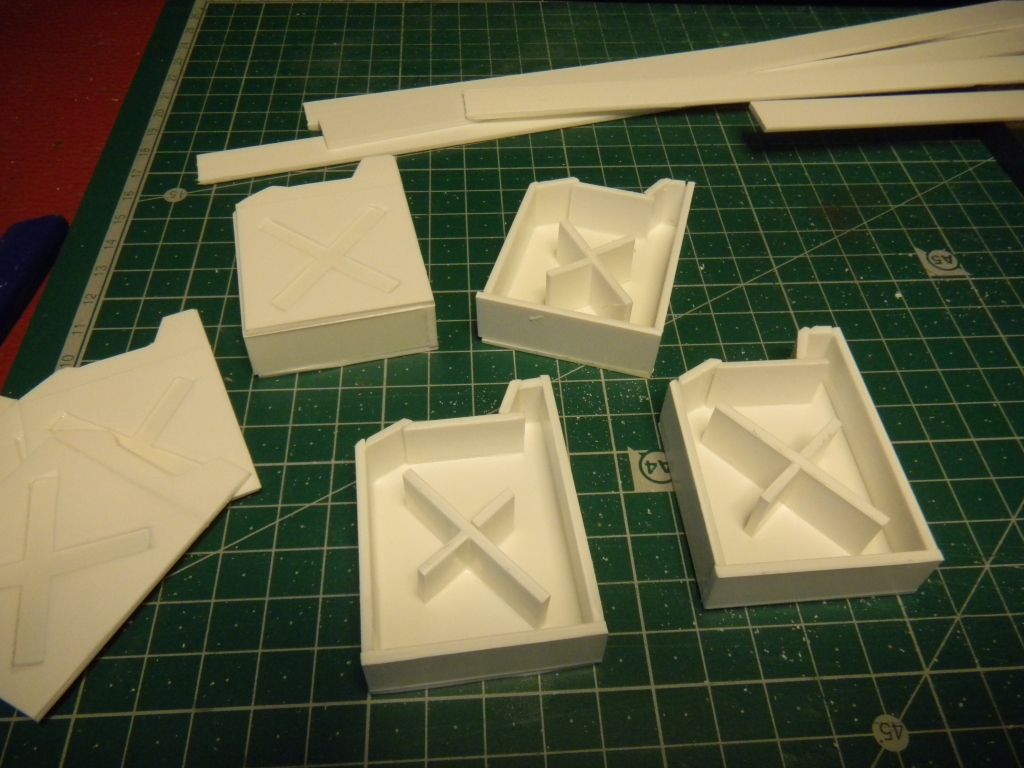

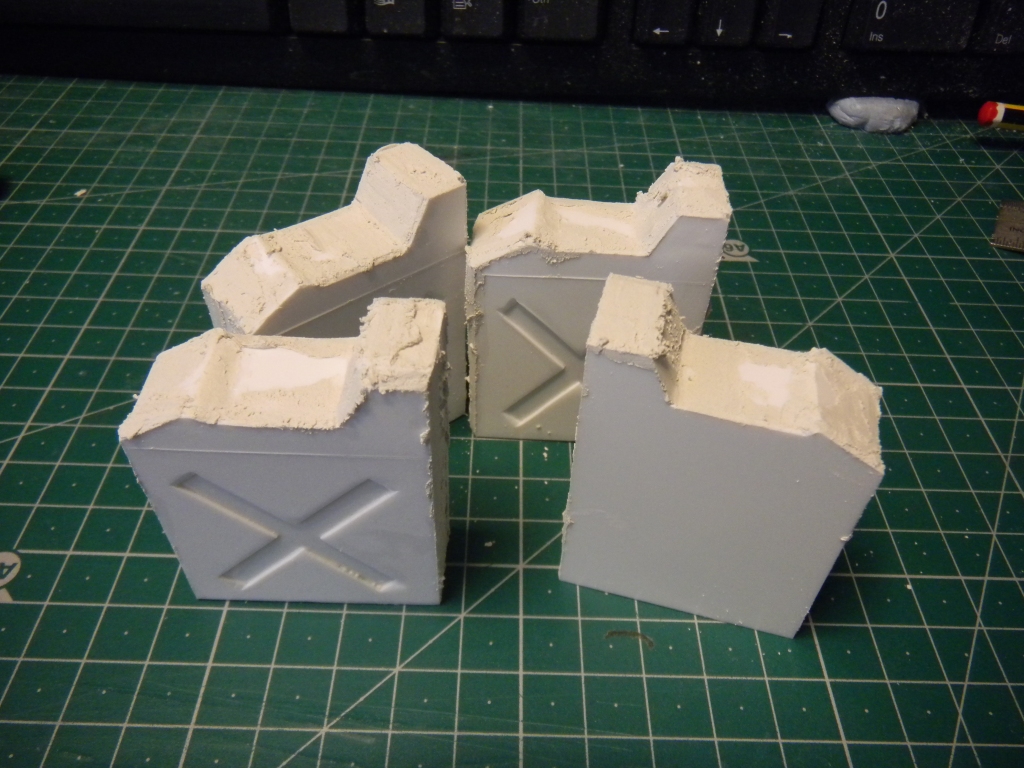

Had hoped to have started on the winch drum, but the still aluminium hasn't arrived so I made some keepers to help locate & protect the swing bearing on the rear axles, and also started on the boxing in on the underside of the chassis. The rear end has a lot of layers & reinforcement as I'm planning to fit a towing eye in that area

|

|

Please Log in to join the conversation. |

8x4 MAZ/MA3 535A from Lunchkins 4 years 9 months ago #55732

|

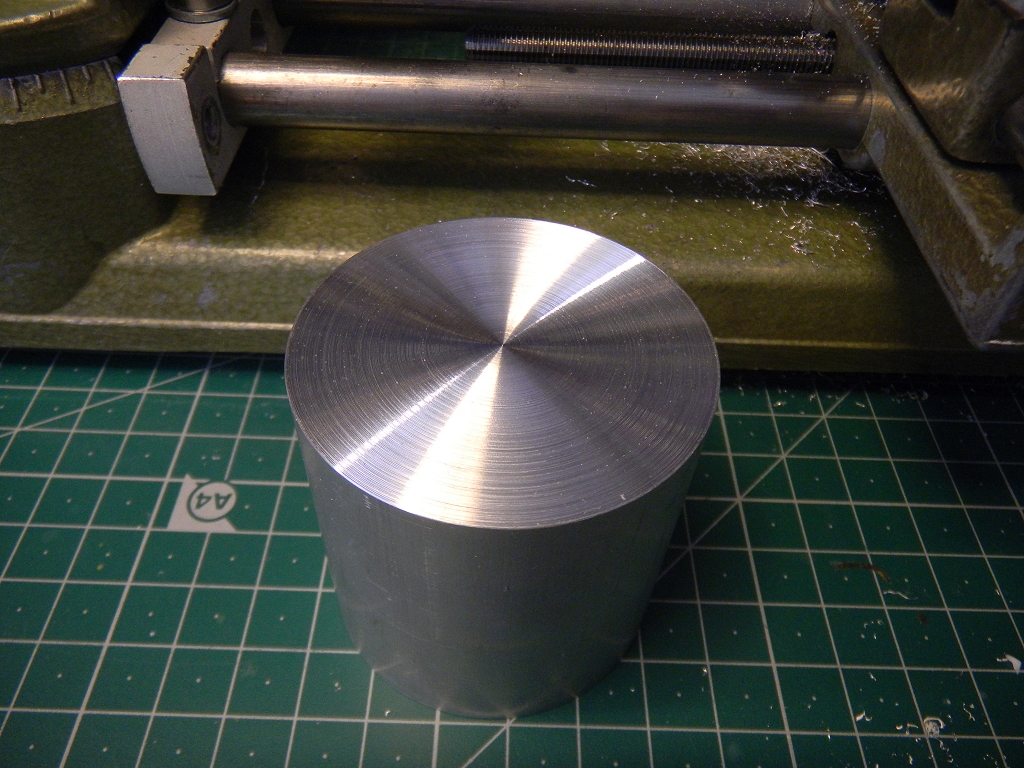

Aluminium finally arrived, facing it off went smoothly enough ...

... as did drilling all the way through on the pillar drill. I didn't get very far before the traverse action on the top slide was seizing up. Nothing was obvious from the outside & cleaning & lubing what I could wasn't helping, so I completely dismantled it & cleaned in the U/S tank ... Back on track, but after several grabs & motor stalls I killed the PSU & speed control. It looks like it's just fuses are the problem, but they are odd types & I can only get them by mail order. I'll probably have it up & running again by the end of next Wednesday, but I've got to question the wisdom of continuing to push the Unimat so obviously beyond its capacity

The following user(s) Liked this: stingray-63

|

|

Please Log in to join the conversation.

Last edit: by Jonny Retro.

|

8x4 MAZ/MA3 535A from Lunchkins 4 years 9 months ago #55735

|

Wow, looking good man!

Ya, that's a big piece of alloy for a unimat and before I had anything bigger I would do such things too. I do recommend you support the free end with a center in the tailstock, It will really help with the digging in problem. And of course take small bites. The mate I sold my old unimat too called me up shortly after he got it because he broke one of the chuck jaws when he did a similar thing turning a longer fat piece of brass unsupported, expensive lesson learned. I think there is an old machinists formula for such things something about 1 1/2 times the diameter and you need to support it, or something like that. The unimat is very capable, there is a riser kit for turning even bigger stock, folks have built some amazing things with them. Despite their obvious design flaws I am still very much a fan of them, for the price and size it is just amazingly handy to have one From somewhere out in the wilds of central Ontario.

.......you build what you like, I will build what I like........it's all cool......

The following user(s) Liked this: Jonny Retro

|

|

|

Please Log in to join the conversation. |

8x4 MAZ/MA3 535A from Lunchkins 4 years 9 months ago #55742

|

Thanks Oldwilly, I can get a live centre in the tailstock to reach with the current setup, which should at least let me finish the end I'm currently working on ... once I've charged up a couple of batteries.

I have the official headstock raising block & made a block to lift the toolpost the same amount, but I'm not aware of anything available to lift the tailstock on the early models |

|

Please Log in to join the conversation. |

8x4 MAZ/MA3 535A from Lunchkins 4 years 9 months ago #55767

|

One advantage of using Anderson Power Pole connectors ...

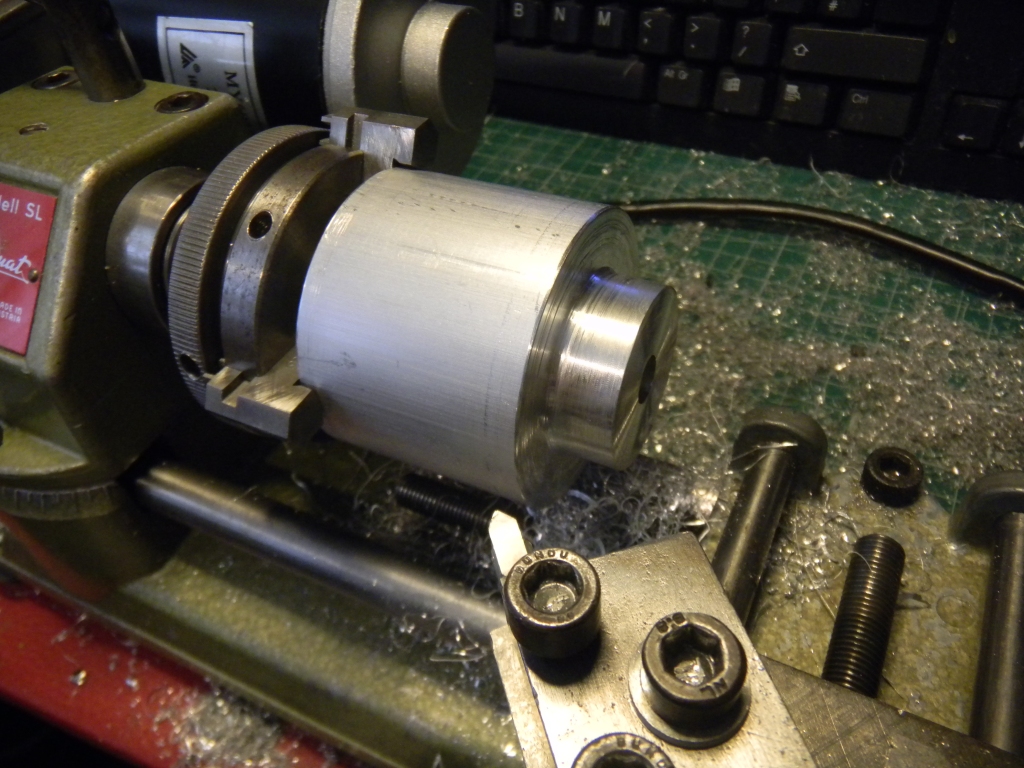

Tail support meant I could finish the end I was working on & start digging out the useful bit, however the diameter was too great to get any part of the slide under it, so had to do the rest unsupported. I gave up chasing the flaws as every time I was getting somewhere, it dug in again. Changes from the "design" were counterboring to 8mm so it would fit the gearbox output shaft |

|

Please Log in to join the conversation. |

8x4 MAZ/MA3 535A from Lunchkins 4 years 9 months ago #55768

|

The following user(s) Liked this: larbut

|

|

Please Log in to join the conversation. |

8x4 MAZ/MA3 535A from Lunchkins 4 years 9 months ago #55769

|

Nice!

|

|

Please Log in to join the conversation. |

8x4 MAZ/MA3 535A from Lunchkins 4 years 9 months ago #55774

|

Fuses for my DIY Unimat PSU arrived - 20mm, 15A fast blow ceramic (2.93 GBP for 5) & 10mm 6.3A slow blow glass with axial leads that need soldering in (3.20 GBP for 3).

Both types installed & PSU reassembled, lathe working as intended again

The following user(s) Liked this: stingray-63

|

|

Please Log in to join the conversation. |

Time to create page: 0.190 seconds