TOPIC:

Re: Kitshack 28" Vosper 68ft RTLL Rescue Launch build 11 years 11 months ago #9093

|

I make it 72 rpm on 6V, 55.5 rpm on 4.8v ... I really want it to be doing 25rpm or so

I'm sure I can do it with a resistor once I work what the servo draws & what the start voltage of the motor is - I suspect that'll be the limiting factor in how slow I can make it go. I know I had a rheostat that would be perfect fof the job (so I could just tweak it & forget it), but I'll be jiggered if I can find it |

|

Please Log in to join the conversation. |

Re: Kitshack 28" Vosper 68ft RTLL Rescue Launch build 11 years 11 months ago #9095

|

There is a quick way to make a servo rotate 360+ at any speed you like - get the top & gears off & look at the pot shaft - it usually has a flat on it. File the flat part down in length so that it doesn't engage the output gear any more, & remove the "stop" from the output gear (As you said earlier). Then, hook the servo up to a 5v supply & gently tweak the pot until the servo is rotating at the required speed. Then fix the pot position (CVA, threadlock etc) & just check the gears run smoothly on the pot shaft without disturbing its position (If it's the type of servo where the gears run on the pot shaft).

Normally, with no signal, a servo will "centre" itself by looking at the position of the pot. If you disengage the pot, the servo will just continue to hunt for this centre position (& never find it). Usually, the further off centre it is, the faster the servo will run. Removal of the stop is to allow the output gear to keep turning. If you plan to go down the rheostat route instead for speed control, be aware that it's likely to have to be a fairly high wattage one (ie heftier than a standard pot), so you might be better off with a fixed value component. Personally, I would've been looking at a small motor with a worm gearbox & drive it via a LM78xx series regulator, but if you've got a spare servo kicking about, then why not....

Custom F2

...

Hilux crossmember drawing

...

F2 axle drawing

...

Quattro radio lid

...

Holiday Buggy motor bracket drawing

...

Quattro resto

...

HitnMiss engine

...

Wild Willy resto

...

Mardave Cobra resto

...

Thunder Dragon resto

...

Grasshopper resto

...

XR311 resto

...

Modded XR311

...

Carbon 25th scratch build

The following user(s) Liked this: Jonny Retro

|

|

|

Please Log in to join the conversation. |

Re: Kitshack 28" Vosper 68ft RTLL Rescue Launch build 11 years 11 months ago #9098

|

Thanks eddrick, I'll give it a try

|

|

Please Log in to join the conversation. |

Re: Kitshack 28" Vosper 68ft RTLL Rescue Launch build 11 years 11 months ago #9102

|

The "no signal" bit threw me, and the fact I'm using a 4/6 channel setup, but I think I got there in the end ... with no signal wire it doesn't work at all, with the signal wire connected it does work, but the TX also has to be on ... and it depends which channel it's blugged into on the RX - 1 & 3 are already occuplied, channels 2, 4, 5 & 7/B cause the servo to spin at full speed, but channel 6 does seem to work - I've got it down to a reliable 19rpm

|

|

Please Log in to join the conversation. |

Re: Kitshack 28" Vosper 68ft RTLL Rescue Launch build 11 years 11 months ago #9105

|

The full speed rotation on 2,4,5,7,B might be down to servo reversing switches - 3 things to note when playing "Vandalise the servo" (1) Often, servo centre position is different when the Tx reverse switch is set "Normal" to when it's set to "Reverse" (You've probably seen this when setting up steering). The 1-3 splines difference can be enough to have the servo hunting for centre at full speed (You probably already discovered how sensitive the pot is whilst trying to find the point at which it reverses direction). The speed normally decreases the closer to centre it is, slowest being just before it stops & changes direction, then increases speed in that direction instead. (2) If you've been a bit heavy handed with the adjustment, or disturbed the pot whilst dismantling the servo, you will probably discover a SECOND reversing point, either side of which the servo rotates at full speed - this is where the feedback from the servo to the Rx doesn't make sense to the Rx any more & the servo tries to find a value that does, as quickly as possible. (3) I don't know about 2.4GHz sets, but certainly with multichannel 27MHz sets, the channels are seperated/defined by the stick pot positions (Read channels as servo numbers on the RX, NOT frequency bands/crystal numbers). Er, best way to explain this..... the transmitter board transmits a simple code (Usually PWM) at a fixed 27.???MHz. The throttle stick resistance will be set to cover a range that gives, say, 1-2v into the encoder, which outputs a PWM range that the RX understands as "Servo #1 full scale left-to-right). The steering stick resistance will be set to cover ANOTHER range, that gives, say, 2.5-3.5v into the encoder, which the RX interprets as "Servo #2 full scale left-to-right). Similarly for the other channels eg CH3 stick set 4-5v, Rx controls servo #3 etc etc etc. Hope that makes sense before I move on, or the next bit won't.... IF there's a bit of an overlap/crossover on the resistance of the Tx stick pots (Say CH1 = 1-2v, CH2 = 1.9-2.9v etc) then when a servo is forced over-range (By messing about with the pot), the Rx can't figure out which channel the feedback is coming from & will try to spin the servo at full speed until the feedback makes sense for CH1 or CH2 etc.

In summary, when messing about with the servo pot, you should find it runs slower the nearer centre it gets. If it doesn't, you've found the false centre, which can lead to channel confusion. If you're messing about with the TX pots, make sure you don't overlap the values for 2 seperate channels, or ther'll be channel confusion, or if you're really careful you could set it up to have 2 seperate channels controlling the same servo, but I can't see that being very helpful! Sorry, yes, some servos require SOMETHING coming in on the signal wire as a reference to centre to or they'll decide they're over-range or there's channel confusion etc & do their best to sort the problem as quickly as they can. Others will just sit there looking dumb with no signal connection, until you tweak the pot

Custom F2

...

Hilux crossmember drawing

...

F2 axle drawing

...

Quattro radio lid

...

Holiday Buggy motor bracket drawing

...

Quattro resto

...

HitnMiss engine

...

Wild Willy resto

...

Mardave Cobra resto

...

Thunder Dragon resto

...

Grasshopper resto

...

XR311 resto

...

Modded XR311

...

Carbon 25th scratch build

The following user(s) Liked this: Jonny Retro

|

|

|

Please Log in to join the conversation. |

Re: Kitshack 28" Vosper 68ft RTLL Rescue Launch build 11 years 11 months ago #9123

|

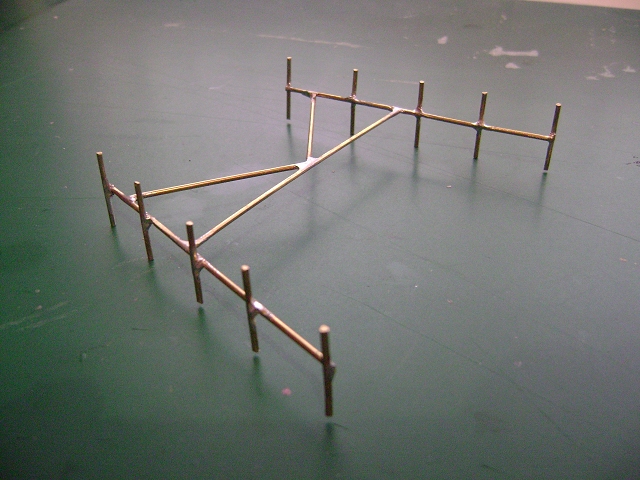

I'm not much cop at soldering, so I've been putting off building the Yagi aerial ... I got there in the end (after I think 30 mins soldering & 45+ minutes filing) ... but there's not enough brass in the kit to do the supports

|

|

Please Log in to join the conversation. |

Re: Kitshack 28" Vosper 68ft RTLL Rescue Launch build 11 years 11 months ago #9190

|

Didn't order all the brass rod I needed to finish the aeriels

I can do some more on the hull though, this is after the 1st coat of sanding sealer - balsa, abachi & birch ply are virtually unchanged, but the pink ply I used on the deck came out a nice hardwood looking colour - I don't think I'll want to stain/paint it - it looks right as it is |

|

Please Log in to join the conversation. |

Re: Vosper 68ft RTLL Rescue Launch build 11 years 11 months ago #9200

|

Moved on to fibreglassing the hull - I started with a long triangular piece to do the keel & onto about 1cm all round it:

The "Z-poxy" resin is, according to the instructions, "odorless". All I can say is they clearly don't have any sense of smell - the hardener smells like 3 day old, umm ... bodily fluids It's also supposed to have a "working time" of 20 minutes, be set in three hours, and sandable after 6 ... again, reality is somewhat different - after an hour there was no sign of setting, after 3 it was about halfway there. It did set overnight though - about 12 hours. Temperature & humidity could have played a part (15C falling to about 10C, RH must have been 80%+), and also inexact measurement - I just squeezed the bottles until the levels were about the same. This morning I did the main bit of the hull, with one sheet of fibreglass cut roughly to shape, with a slot for the keel & cuts to allow a little overlap on the stern: This time I was very careful about the quantities of resin & hardener - 30ml of each, measure with syringes. Again the working time quoted was hopeless, just as well really as it took about an hour to get it all applied, spread, the fibreglass on, soaked through & smoothed out ... I've left the edges to do their own thing, when the resin is all set I'll trim/sand back the excess, I'm hoping to use the same resin to seal & strengthen the deck too (just without the fibreglass). I've also done a bit more on the mast (some of that cross bracing was very fiddly), hopefully the brass rod will arrive soon & I can finish off the metal aeriels.

The following user(s) Liked this: AndyAus

|

|

Please Log in to join the conversation.

Last edit: by Jonny Retro.

|

Re: Vosper 68ft RTLL Rescue Launch build 11 years 11 months ago #9201

|

Forgot to mention there is now a Tamiya part on it - a piece of aeriel tube to transfer the power from the servo to the radar dish

I've also been thinking about colours for paint - sources vary, but in general they suggest red (antifouling) below the waterline, black up to the deck, grey deck & cabins, apart from the roof of the main one, which is white... I've already fouled up that scheme by having a planked wooden deck, and grey is a bit dull ... and I don't like the idea of black on it too much either - I'm thinking red oxide for the bottom of the hull, medium to dark blue up to the deck, "natural" wood deck, grey for the deck part of the removeable superstructure, and like for all the bits on it |

|

Please Log in to join the conversation. |

Re: Vosper 68ft RTLL Rescue Launch build 11 years 11 months ago #9205

|

Re the GRP setting times - yes, you need to keep it warm to get it to set (Note the temperature range in the instructions, it's fairly important). Mix ratio isn't critical, as long as you always add more catalyst than is specified. Normally, adding more catalyst will make it cure quicker, but will make it get hotter the more you over do it, so just be careful (With extreme mixes, it can get hot enough to set fire to combustibles, we've had a couple of factory fires from careless mixing). If it's still taking a long time to set, after you've tried warmth & a stronger ratio, it might be the catalyst has had it - some don't have a very long shelf-life, normally close to how long it's likely to sit on a model shop shelf. If the resin is a polyester based type, you could try using catalyst that comes with "Isopon" car body filler, (Obviously test it works before doing anything important with it), you should expect a 10-30 minute cure time with it if it works (With 10:1 resin:catalyst mix).

Cool idea using aerial tube as a flexi-drive! Another goodun is to use aircraft control tubes for flexible linear motion actuators (Bourdon tubing? - one tube inside another)

Custom F2

...

Hilux crossmember drawing

...

F2 axle drawing

...

Quattro radio lid

...

Holiday Buggy motor bracket drawing

...

Quattro resto

...

HitnMiss engine

...

Wild Willy resto

...

Mardave Cobra resto

...

Thunder Dragon resto

...

Grasshopper resto

...

XR311 resto

...

Modded XR311

...

Carbon 25th scratch build

|

|

|

Please Log in to join the conversation. |

Time to create page: 0.143 seconds