|

|

|

TOPIC:

Help needed on a constant current power supply... 12 years 1 week ago #8917

|

Hi guys,

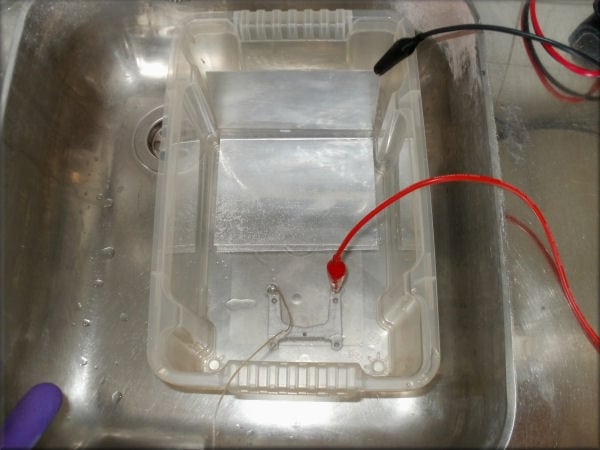

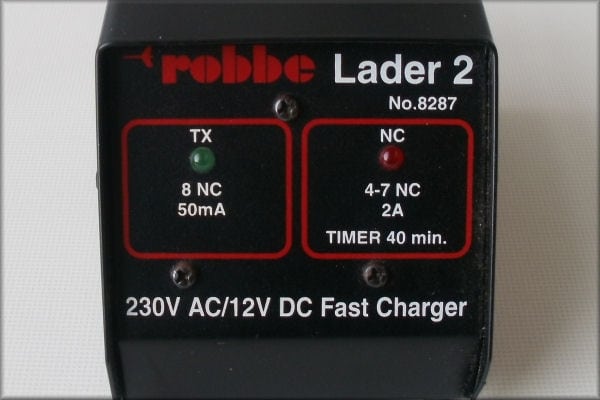

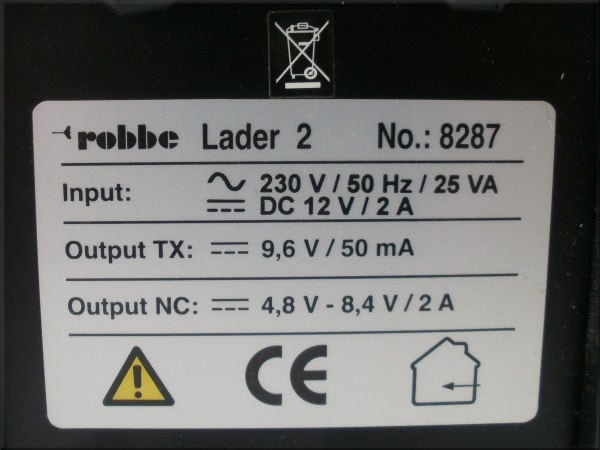

I have been doing some experimenting with anodising aluminium parts but I am a bit stuck in the process. Some items go very well and some not at all. Depending of the specific material. I think I have figured out why this is... So far I have been using the "constant voltage" method which means using a regular power supply or car battery. The voltage is set and the current should then run (and vary) on it's own. But with some sorts of aluminium, this current stops swiftly. This is because the anodisation process creates a layer on the material that starts working as an insulator. So the next step would be to switch to a "constant current" or "current regulated" process. With this the current is set and the voltage varies... But which power supply is suitable for this or how do I make one? Furthermore - could I use this 2A NiCad charger as a basis? Or will it go up in smoke... Hope y'all can help me to make some more progress. |

|

|

Please Log in to join the conversation.

Last edit: by Edou.

|

Re: Help needed on a constant current power supply... 12 years 1 week ago #8921

|

I wish I could help, but my electrical skills just don't allow me

-Lars Signature now gets correct formatting if you edit it in your Profile. Use normal BBcode if you want.

www.tamiyabase.com was formatted automatically. |

|

|

Please Log in to join the conversation. |

Re: Help needed on a constant current power supply... 12 years 1 week ago #8923

|

As long as the voltage you inserting into the water is DC you should be fine. It's no different to shorting the dc voltage together. I used a 12 volt DC power supply and a thin piece of wire to cut polystyrene. The shorting causes the wire to get hot, and it cuts with o problems.

It's worth a try... My Projects:

Bullhead Rebuild ... Ford F350 Mods ... Manta Ray Revival ... Custom Super Hornet Build ... TL-01 Crawler ... CC-01 Pick-up ... CR-01 With Hop ups ... Project Unknown ... Clod crew cab ... Other: Custom Display cases ... Limited Slip Diff(LSD) ...

The following user(s) Liked this: Edou

|

|

|

Please Log in to join the conversation. |

Re: Help needed on a constant current power supply... 12 years 1 week ago #8935

|

How heavy is that power supply? - if it's got some weight to it, it'll be a transformer (Rather than a switch mode (Electronic)) type, & the output will be too coarse I would have said - rectified (AC to DC conversion) transformer outputs aren't true DC, more a buzz of + & - pulses (Pretty much what the diagram on it shows). This doesn't matter for battery charging as the battery acts as a damper, smoothing out the bumps & missing bits. I'd also say the current is too low & it'll get hot if the bath can draw anywhere near the 2A max rating. It won't go bang, but it will probably get hot & activate the internal thermal trip.

You could try an old laptop power supply, or banks of toy car batteries connected in parallel & series to get the voltage & current you need (Series for more volts, parallel for more amps). I still think you need to be looking elsewhere for your problems with this as it seems most DIYers are using 12V auto batteries. I read somewhere that the insulating layer that can build up is contaminants in the electrolyte, associated with dirty electrodes, dirty electrolyte or dirty aluminium parts, & they were saying everything has to be scrupulously cleaned & degreased & don't handle the parts after cleaning as finger grease is enough to stop it working

Custom F2

...

Hilux crossmember drawing

...

F2 axle drawing

...

Quattro radio lid

...

Holiday Buggy motor bracket drawing

...

Quattro resto

...

HitnMiss engine

...

Wild Willy resto

...

Mardave Cobra resto

...

Thunder Dragon resto

...

Grasshopper resto

...

XR311 resto

...

Modded XR311

...

Carbon 25th scratch build

The following user(s) Liked this: Edou

|

|

|

Please Log in to join the conversation. |

Re: Help needed on a constant current power supply... 12 years 1 week ago #8937

|

The Robbe (charger) feels quite heavy...

Until now I've been using a Graupner (adjustable voltage) power supply that is more of a lightweight (literally) : I suspect it's not a case of contamination of the acid or a lack of proper prepping. The process has been showing the same characteristic since I started and I take good care with the parts to be anodised. One of the shock towers I succesfully dyed, drew a current of about 1.5A at 15V... Maybe I'll try the Robbe 2A charger with an ever so small item - like a Group C motor mount that wouldn't work before. That might show if it functions at all... Thanks for your input so far, guys. |

|

|

Please Log in to join the conversation.

Last edit: by Edou.

|

Re: Help needed on a constant current power supply... 12 years 1 week ago #8939

|

Why not just try the Robbe, a course supply might even work better, you never know. Just keep an eye on it though, & turn it off if it gets hot quick or makes any odd noises. You could also try something with more beans behind it, say an automotive battery charger? Same precautions would apply though. Did you ever get around to trying it with the connections reversed?

Talking of contaminants, it might even be that they're in the metal in the first place - a lot of cast parts are made from recycled ally, which in the case of toy car bits (& Lawnboy mowers) is likely to be less pure cheapy stuff. The info I've been reading has been where DIY people are making the parts from scratch (New metal) or where manufacturer's are doing it (They'd buy the most compatible materials?)

Custom F2

...

Hilux crossmember drawing

...

F2 axle drawing

...

Quattro radio lid

...

Holiday Buggy motor bracket drawing

...

Quattro resto

...

HitnMiss engine

...

Wild Willy resto

...

Mardave Cobra resto

...

Thunder Dragon resto

...

Grasshopper resto

...

XR311 resto

...

Modded XR311

...

Carbon 25th scratch build

|

|

|

Please Log in to join the conversation. |

Re: Help needed on a constant current power supply... 12 years 1 week ago #8941

|

Strangely enough cast aluminium parts make the process go easiest.

Most likely because the other ("contaminating") metals in it make the part more conductive... In itself the anodisation works, so it's not a case of reversed polarity. I accidentally did a +/- switcheroo at some point which resulted in a 4-5A anodisation of the cathode plate! The Graupner is probably just not very suited for what I'm doing here. Like you said - not enough beans. I may give a car battery (or similar) a try too... |

|

|

Please Log in to join the conversation. |

Re: Help needed on a constant current power supply... 12 years 1 week ago #8944

|

Er, thought train... cast is usually quite porous, so if you say that works best, maybe look at your etching method (The caustic dip bit) - try it for much longer or with a stronger caustic solution to see if that makes a difference. The best off the shelf caustic I've used (For cleaning 2-stroke bike exhausts) is the granulated drain cleaner stuff, you know when you've got a strong mix cos it'll get hot as you're mixing it (....& will melt the plastic container you're mixing it in if you get a bit heavy handed with the granules). Some people recommended the use of nitric acid, but like I said in PM, you don't want to be messing about with that stuff, it's proper nasty poisonous (Including the fumes)

Custom F2

...

Hilux crossmember drawing

...

F2 axle drawing

...

Quattro radio lid

...

Holiday Buggy motor bracket drawing

...

Quattro resto

...

HitnMiss engine

...

Wild Willy resto

...

Mardave Cobra resto

...

Thunder Dragon resto

...

Grasshopper resto

...

XR311 resto

...

Modded XR311

...

Carbon 25th scratch build

|

|

|

Please Log in to join the conversation. |

|

|

|

Time to create page: 0.393 seconds