TOPIC:

Re: Carbon Group C - F1 Ferrari F40 12 years 2 months ago #7270

|

Thanks, that looks like cool stuff. But maybe for another project 'cause I do have a plan for this one...

I'm curious about that stuff though and how flexible it actually is for making a T-bar out of it. Don't think one should be hacking into such a carbon sheet without proper health precautions in any case... |

|

|

Please Log in to join the conversation. |

Re: Carbon Group C - F1 Ferrari F40 12 years 2 months ago #7272

|

the sheet i bought,is really a vinyl texture sheet but you heat it with a hair dryer and it forms almost any shape you want, just an idea

www.ebay.co.uk/...6240wt_821

The following user(s) Liked this: Edou

|

|

|

Please Log in to join the conversation. |

Re: Carbon Group C - F1 Ferrari F40 12 years 2 months ago #7273

|

That's nice stuff at a bargain price. I think I'll get some of that for the wing of my DF-01.

I could also use it if I ever happen to find another body for this car. This chassis will stay natural though. Polished FRP looks pretty awesome too... |

|

|

Please Log in to join the conversation.

Last edit: by Edou.

|

Re: Carbon Group C - F1 Ferrari F40 12 years 2 months ago #7274

|

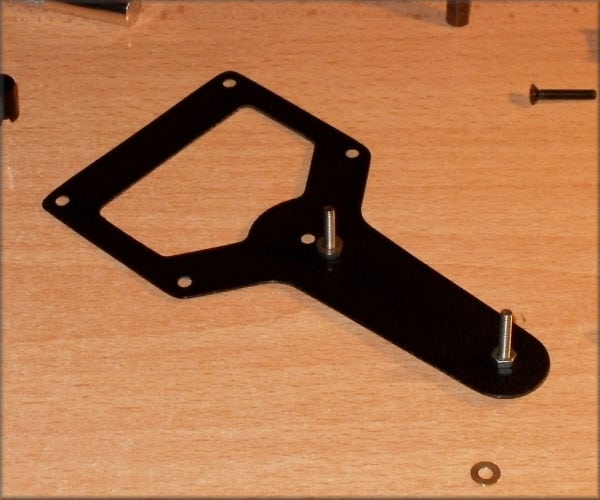

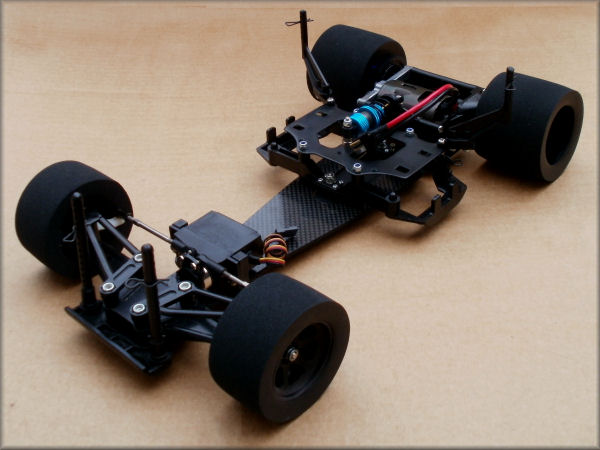

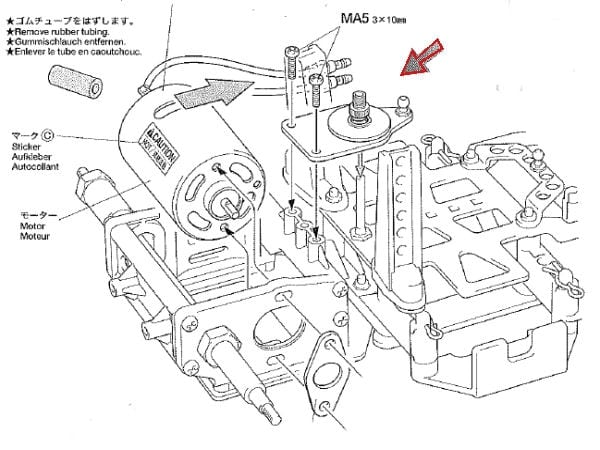

Some more details of how I put it together...

I used an F102 (Group C) T-bar with an extra hole drilled in it to fit a flexible tray holder from the F103. Titanium screws with nuts on them to heighten the tray slightly so the T-bar will align with the chassis : These 2mm bolts are put in the flexible joint of the battery holder to limit the maximum roll angle of the T-bar : Got these nice little hex heads in the mail yesterday from Ducdennis on the Dutch forum. The length is very compatible and a big advantage of these is that I can adjust them by using a basic grub screw wrench. For now the T-bar's stiffness on the chassis is not yet a variable but it's maximum role is... A Group C motor case with a Sport Tuned (Deans plugged) and Racing Developed 0.4mod pinion and spur... Carbon rear axle for an F103GT with Group C wheels hubs and C11 wheels: Carbon chassis plate, TRF damper and of course the vintage aluminium motor heatsink from Lars : And a bunch of trial and error... |

|

|

Please Log in to join the conversation.

Last edit: by Edou.

|

Re: Carbon Group C - F1 Ferrari F40 12 years 2 months ago #7275

|

Re health issues cutting carbon fibre - you need to be wearing a mask when cutting drilling, working with ANY kind of ceramic fibre impregnated material - it can all be as lethal as asbestos - the breathed in fibres get stuck in your lungs causing irritation that usually leads to cancer. Best one is ceramic dust (Sanding dry clay included). They call the condition silicosis, the symptoms are the same as asbestosis, but without the asbestos

Custom F2

...

Hilux crossmember drawing

...

F2 axle drawing

...

Quattro radio lid

...

Holiday Buggy motor bracket drawing

...

Quattro resto

...

HitnMiss engine

...

Wild Willy resto

...

Mardave Cobra resto

...

Thunder Dragon resto

...

Grasshopper resto

...

XR311 resto

...

Modded XR311

...

Carbon 25th scratch build

|

|

|

Please Log in to join the conversation. |

Re: Carbon Group C - F1 Ferrari F40 12 years 2 months ago #7290

|

Here's my experiment to fit an F103 T-bar... without success yet but I did get a good idea of the dimensions.

Once more the difference between that of an F103 (left) and an F102-Group C : Total length of the left one is 3mm more and it's sideways offset is 4.5mm. Why do I want to use the lopsided one? Because it would match the wheel base of the body a bit better. But more importantly - I will then be able to install the F103 motor mount cross parts also... They allow for the fitting of an friction plate to add an extra option for adjusting T-bar roll : But I'll have to shift the rear axle 4.5mm in the opposite direction if I want to use Group C axle parts and wheels! Something I discovered led me upon the path of mixing, matching and trying : The distance between the side of a Group C (F101-F102) motor case and the wheel stopper is 20.5mm : Adjusting 4.5mm would leave 16mm - which happens to be the length of the spacer the F103GT uses. And I have that here! So I dreamt up this combo : Almost right! But at the same time totally not... Question of the day : why doesn't this work at all? I am a long way on the right track though... |

|

|

Please Log in to join the conversation. |

Re: Carbon Group C - F1 Ferrari F40 12 years 2 months ago #7306

|

That F103 rear axle assembly's a rum thing! Why have they gone for a plain axle with threaded hex adaptors? Would've been cheeper to manufacture an axle with threads both ends & have the hex adaptors tubular fixed with grubscrews. IF you had a lathe, that could be another answer... Er, way around that would be to buy 5mm(?) silver steel & thread it both ends (For the axle), & buy some aluminium hex bar & cut it to the size of your hexs & drill them through So they can be positioned anywhere on the shaft) & grubscrew them to the shaft to fix. Then, get some 5mm I/D aluminium tube & cut it to the required lengths for spacers. With a bit of care it should be possible done in a vice with a hacksaw & power drill, only thing that really needs to be fairly accurate is drilling the hexs.

I still say slot the holes or remake a longer symetrical T-bar - the friction damper doesn't look like it would be difficult to make, but what's the story with the wheels?

Custom F2

...

Hilux crossmember drawing

...

F2 axle drawing

...

Quattro radio lid

...

Holiday Buggy motor bracket drawing

...

Quattro resto

...

HitnMiss engine

...

Wild Willy resto

...

Mardave Cobra resto

...

Thunder Dragon resto

...

Grasshopper resto

...

XR311 resto

...

Modded XR311

...

Carbon 25th scratch build

|

|

|

Please Log in to join the conversation. |

Time to create page: 0.189 seconds