TOPIC:

My body post crossmember project 11 years 6 months ago #13569

|

Hi guys,

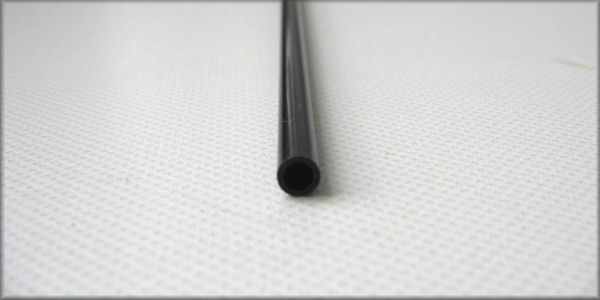

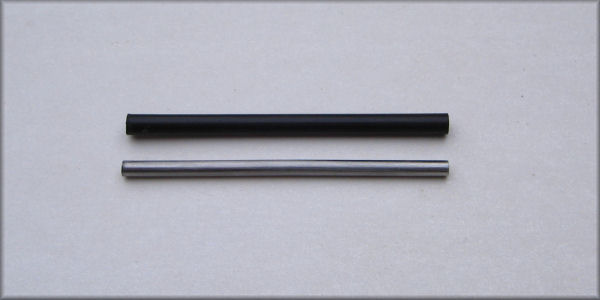

I thought I'd start another separate topic about a side project that evolved from my Humvee DF-01 build. To give the body posts more constructive coherence, I've been brainstorming about fabricating some crossmembers. With a good design they can even function to make the shell height adjustable. First bit I made was "waste" from a B parts tree (rear gearbox)... Drilled some holes into that so the body clips could fit : Put small pieces of heatshrink back in so they would fit more snuggly... Although this isn't too bad and nicely height adjustable, it's not really giving any extra structural strength : Next idea was using carbon tube, tap 2mm threads into that and tighten them through the body posts with 2mm screws. I thought I ordered 4mm tube with an inner diameter of 0.5mm. I would enlarge that to 1.5mm and then tap a 2mm thread into it... But it turned out 0.5mm was the wall thickness - leaving an inner diameter of 3mm. Too large for a 2mm screw : Making me rethink the plan. Next idea - fill up the carbon tube with 3mm round metal and tap a 2mm thread into that. Without using the internet, the closest thing at hand was stainless steel : Didn't fit straight away. First I had to take a 3mm drill through the tube (by hand). And I was being very optimistic. With my limited tools, I will never get enough accuracy to drill and tap a 2mm thread into a 3mm rod. And the stainless is much harder than I expected... So I'm gonna shorten it and only use it as inner strengthening of the carbon : On each side there is now 5.5mm left - room to glue in M2 helicoils : A much more complicated design than I anticipated on but that happened on the fly... They should be very strong and pretty high tech when it's all put together though. I'll have to wait on the helicoils to proceed any further... Gonna make a couple more in the meantime. One for structural purpose on each set of body posts - and another for adjusting height. |

|

|

Please Log in to join the conversation.

Last edit: by Edou.

|

Re: My little high tech crossmember project 11 years 6 months ago #13572

|

Carbon tube is tough to work on...

First of all the dust and fibres are hazardous but it's also not easy to cut right. Not being careful means the tube will split at the ends. First thing I did when I succeeded in cutting a decent piece, was put some CA glue on the end to prevent splitting. Looking for M2 screws, I came across an affordable bag with many of the ones I was looking for. Who knows for which car that could be - without googling? I'm sure the tiny diff pin will come in handy on a future project. |

|

|

Please Log in to join the conversation. |

Re: My little high tech crossmember project 11 years 6 months ago #13582

|

Aha, that's what you're up to...

Sorry, but drilling 1.6 into a 3mm stainless rod just ain't gonna happen. I'd be nervous about doing that on the lathe.... Good idea with the helicoils, but a suggestion here too - you can buy threaded inserts (For use in plastic), that are knurled on the outside & split at the end. These expand & grip the material as you screw the screw home, & lock themselves into place (A bit like a Rawlpug, but much smaller, & made of brass usually). Wish I knew what they were called, as they'd probably be good for repairing stripped threads in plastic chassis etc. Tip for cutting carbon fibre tube - poke a solid rod up it first, that stainless would work well... then use a fine-tooth (Junior?) hacksaw to cut it. The support should stop it splitting

Custom F2

...

Hilux crossmember drawing

...

F2 axle drawing

...

Quattro radio lid

...

Holiday Buggy motor bracket drawing

...

Quattro resto

...

HitnMiss engine

...

Wild Willy resto

...

Mardave Cobra resto

...

Thunder Dragon resto

...

Grasshopper resto

...

XR311 resto

...

Modded XR311

...

Carbon 25th scratch build

|

|

|

Please Log in to join the conversation. |

Re: My little high tech crossmember project 11 years 6 months ago #13589

|

Good tips once more. Gonna do a google search on the inserts.

I was already glad waterbok gave me the correct term for helicoils on the steering assembly project. All I could think of at first was "a double sided grub screw, but larger" which could have taken a while to find. |

|

|

Please Log in to join the conversation. |

Re: My little high tech crossmember project 11 years 6 months ago #13595

|

I think you guys mean those plugs that are used for wooden funiture.

found them Brass Anchors and these , mmm nice stuff gets me thinking of improving and fixing some plastic tamiya parts.

The following user(s) Liked this: Edou

|

|

|

Please Log in to join the conversation. |

Re: My little high tech crossmember project 11 years 6 months ago #13603

|

Yes, the second ones are what I'm on about

Custom F2

...

Hilux crossmember drawing

...

F2 axle drawing

...

Quattro radio lid

...

Holiday Buggy motor bracket drawing

...

Quattro resto

...

HitnMiss engine

...

Wild Willy resto

...

Mardave Cobra resto

...

Thunder Dragon resto

...

Grasshopper resto

...

XR311 resto

...

Modded XR311

...

Carbon 25th scratch build

|

|

|

Please Log in to join the conversation. |

Re: My little high tech crossmember project 11 years 6 months ago #14159

|

Still waiting on the M2 helicoils...

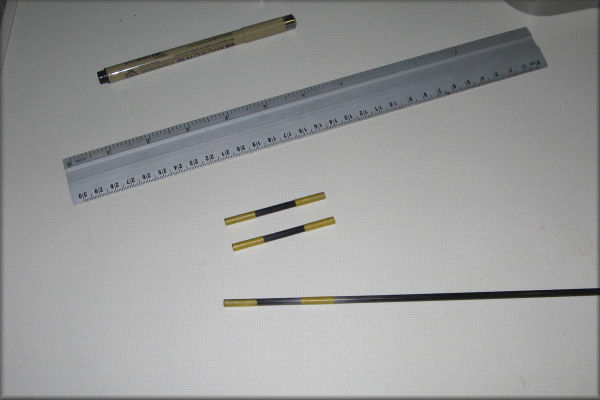

But I've cut the rest of the crossmembers in the meantime : Putting some masking tape at the ends serves multiple purposes - it's a good indication where to cut exactly, it'll somewhat keep the carbon from splitting and any CA glue used won't end up on the outside (and look bad). I couldn't take this approach because I had to cut the rods first and then drill them up to 3mm so the stainless'll fit. For some reason the inner diameter is smaller than the specs would make you believe. Doing this drilling by hand gave me a pretty sore thumb... Only when I was done did I realise I could have probably used the new tap handle for that. For cutting the tube, I took a new approach. I went as slowly as possible and didn't go through in one motion - I changed the angle of the carbon regularly. The last remaining (tiny) bit (most vulnerable to splitting) I didn't saw but cut through with my hobby knife... |

|

|

Please Log in to join the conversation.

Last edit: by Edou.

|

Time to create page: 0.232 seconds