TOPIC:

Re: Motor wiring conventions 11 years 6 months ago #14897

|

Interesting subject, interesting history - I'd always assumed it was only modifieds/tuned that had their terminals marked, (So you get tuned rotation right), & it's only been recently (With the appearance of metal-ended motors) I've noticed standard cans have polarity markings also, which was what made me look, to find out "why".

If you say that vintage motors are also polarity marked, it would suggest that the manufacturer intends the motors to run in one particular direction, despite the fact that they get fitted/used in both, & that idea has been about for some time

Custom F2

...

Hilux crossmember drawing

...

F2 axle drawing

...

Quattro radio lid

...

Holiday Buggy motor bracket drawing

...

Quattro resto

...

HitnMiss engine

...

Wild Willy resto

...

Mardave Cobra resto

...

Thunder Dragon resto

...

Grasshopper resto

...

XR311 resto

...

Modded XR311

...

Carbon 25th scratch build

|

|

|

Please Log in to join the conversation. |

Re: Motor wiring conventions 11 years 6 months ago #14900

|

I think it is more simple than that. I think any manufacturer would want to know easily which direction the motor will run when wired up, without testing each one. The reason for this will be that the end product (be it a toy car, electric drill or whatever) will be designed for a certain motor rotation and time is money. It therefore makes sense to mark the terminals on a motor for reference.

My original question was more "does the yellow wire normally go on the +ve or -ve terminal of the motor". This was not for correct motor rotation because that is easily tested and corrected, but more for aesthetic "correctness". The electrons don't care what colour the insulation on the wire is! Now, I think that all motors MUST be wired the same because otherwise the Tamiya instructions to "connect yellow MSC wire to green motor wire" etc would be useless. Amirite? |

|

Please Log in to join the conversation. |

Re: Motor wiring conventions 11 years 6 months ago #14932

|

Yep, the terminals are marked for reference, but as far as I know there's no "standard" that says "All DC brushed motors must be built to preferentially run clockwise, terminals should be polarity marked to give this preferential rotation" - I think individual manufacturers polarity mark the terminals so that the motors run in the direction that is preferred with respect to how that manufacturer builds their particular motors, the direction that would give best service life with least potential faults.

Like you say, the electrons don't care which way they're travelling in the wire or what colour the wire is, they're just making the magnetism. What's important direction-wise is how the static connection to rotating parts will behave in a mechanical way. Of course the electrons have to travel in a certain direction to cause rotation in a certain direction, but with respect to polarity markings, that will be determined by how the motor is wound. Of course I could be talking rubbish, but it makes sense to me even if it doesn't apply! The way I'm looking at it is this - consider an upturned bicycle. Spin a wheel, then, with the wheel spinning away from you, hold a stick (Facing away from you) against the tyre - the stick just rubs on the tyre. If you then do the same thing, but with the wheel spinning towards you, the stick digs into the tyre & breaks, right? - That's how I'm looking at the brush arrangement in a cheapy silvercan, & that's why I'm saying that there is a preferred rotation direction for a motor with this brush setup. Ok, the motor will run both ways, but theoretically it should only be run in the preferred direction, hence the polarity marks? Like I said, I might just be the first person sad enough to have ever thought about it & it doesn't actually matter... We don't actually know if "yellow always = +ve" or if the yellow & green are attached in such a way as to give clockwise rotation when the motor is RHS mounted, & the only way to find out is to look at a selection of old/new motors from different manufacturers (Johnson, Mabuchi etc) to see if they're all wired the same way. (Pause for thought) It might even be that Mabuchi/Johnson etc are supplying batches of clockwise/anticlockwise motors to suit the different Tamiya motor/gearbox setups, but unless we actually look, how would we ever know? The assumption that the yellow/green connection instruction in the manual is "right" is a dangerous one. Tamiya don't know what radio gear you're using, if the servos turn left or right with "Stick up" or if there's any provision with your gear to reverse the servo action. eg as Jonny said, back in the oldern days, you'd connect everything up as per the manual, only to find that everything worked backwards, & the only way to correct it was to swap the wires to be the exact opposite of what the manual was instructing you to do. There is definately no standard "forward stick = clockwise servo rotation", it depends on the particular radio &/or manufacturer. eg Acoms AP427 - I can tell you that on some of these sets, but not all, the throttle channel works in reverse to the AP227, & I can also tell you that some sets were supplied with servos that work in reverse to others (Re AS2 & AS3). Pick up a vintage Sanwa set of similar age, & depending on the model, will work in reverse to an Acoms set. Phew... getting back to the point... Look in the Brat manual, to see if the "Setting up the MSC" bit actually specifies which way the MSC turns to give car-forward. Trace battery +ve (Red) through the MSC contacts in "forward" to see what colour wire +ve comes out of. Connect green/yellow motor wires to the MSC green/yellow wires, as per the manual. Solder the motor wires to the motor whichever way around causes your wheels to go forward. This at least would have the wiring/colours "correct" as per the manual. Then all you'd have to do is use your tranny servo reversing switches to give "forward stick = car forward". If you're tranny hasn't got servo reversers, swap the motor connections - politically, this is still correct as it would be the situation you'd probably be faced with back in the early 80s, unless you owned some new Futaba Attack radio!

Custom F2

...

Hilux crossmember drawing

...

F2 axle drawing

...

Quattro radio lid

...

Holiday Buggy motor bracket drawing

...

Quattro resto

...

HitnMiss engine

...

Wild Willy resto

...

Mardave Cobra resto

...

Thunder Dragon resto

...

Grasshopper resto

...

XR311 resto

...

Modded XR311

...

Carbon 25th scratch build

|

|

|

Please Log in to join the conversation. |

Re: Motor wiring conventions 11 years 6 months ago #14945

|

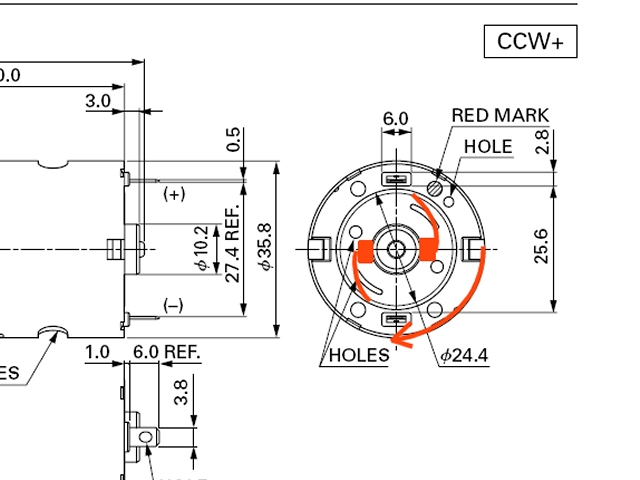

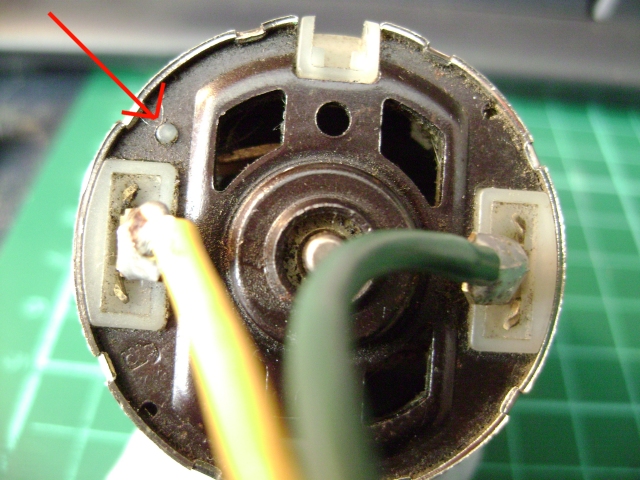

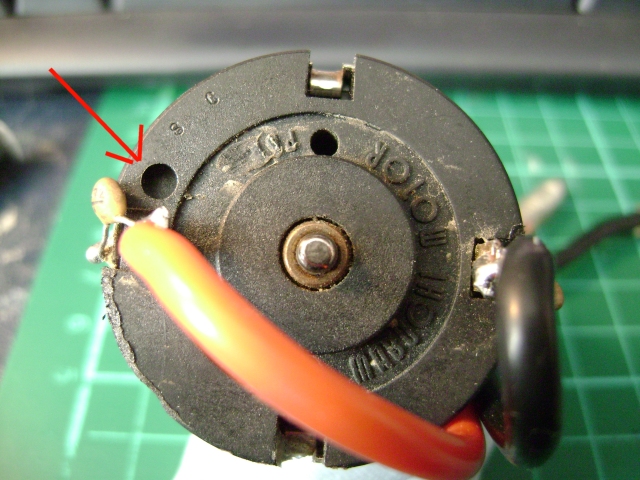

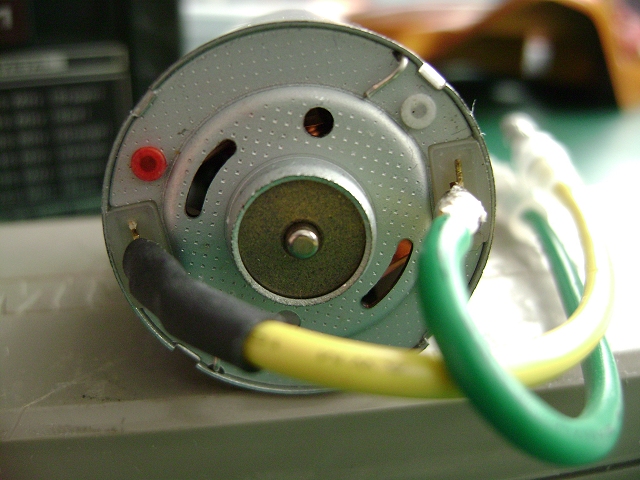

Nor me - but it would make sense, at least within classes of motors, e.g. all "RSxxx" type motors by any manufacturer would be the same electrically/rotationally as well as dimensionally ... Can't say I did a huge amount of research (i.e, stopped when the first thing I found confirmed what I was thinking), but I did find a PDF datasheet for modern 540 motors: www.robotstoreh...40rhsh.pdf ... comparing that to a 540 of the same vintage, and every other loose motor I have that I could see in well enough to judge, the direction of rotation is away from the root of the brush springs. Also took a couple of photos of earlier 540 motors showing the +ve terminal identifier I also found that the RS series was first made in October 1963 ... so that would be, what, 46 years(?) until there was another viable option for RC cars |

|

Please Log in to join the conversation.

Last edit: by Jonny Retro.

|

Re: Motor wiring conventions 11 years 6 months ago #14951

|

Fantastic, cheers Jonny!

& yes I agree, all motors of part number RSxxx will be built to give the same preferred rotation direction, same wire gauge, same rotor type, same dimensionally, same mountings etc

Custom F2

...

Hilux crossmember drawing

...

F2 axle drawing

...

Quattro radio lid

...

Holiday Buggy motor bracket drawing

...

Quattro resto

...

HitnMiss engine

...

Wild Willy resto

...

Mardave Cobra resto

...

Thunder Dragon resto

...

Grasshopper resto

...

XR311 resto

...

Modded XR311

...

Carbon 25th scratch build

|

|

|

Please Log in to join the conversation. |

Re: Motor wiring conventions 11 years 6 months ago #15052

|

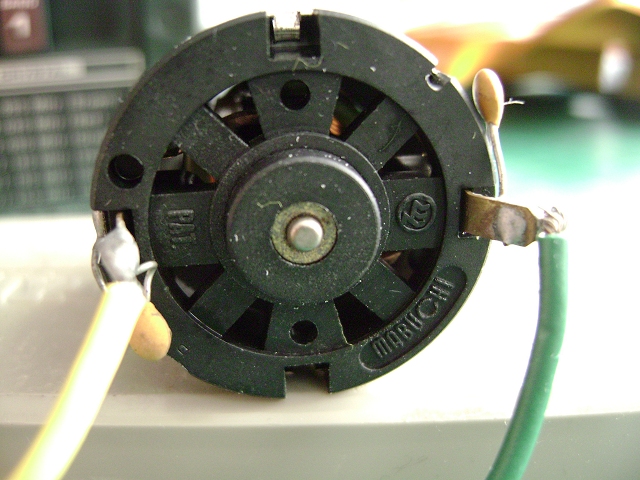

A couple of 380 motors:

Modern one (Grasshopper re-re, Holiday Buggy re-hash, etc), note red +ve marker dot; forward spin is away from the brush roots: Old one (from a vintage Sand Rover), note recessed +ve indication, spin is as above/every other motor; yellow/green wiring is what Tmaiya did many, many years ago: |

|

Please Log in to join the conversation. |

Re: Motor wiring conventions 11 years 6 months ago #15054

|

So it looks like yellow goes to the terminal with the mark in every case. Then the car wiring is made to suit the "correct" motor rotation for forwards motion with the associated movement of the MSC.

|

|

Please Log in to join the conversation. |

Re: Motor wiring conventions 11 years 6 months ago #15061

|

Thanks Jonny, that's at least 2 of us who've learned something today! It's also confirmed my suspicions regarding direction vs brush springs.

Although it's common to see wiring where the +ve "hot" wire is coloured with a "hot colour" (eg, red, brown, yellow, white, orange, vs black, blue, green etc for -ve), there are no standards to say it HAS to be that way, so it can be a bit dangerous to assume this is always the case. At this point, it might be interesting to follow this through to the MSC, calling yellow +ve, to see which way the MSC plate turns to connect yellow to battery +ve/red. It might prove that Tamiya have been careful to maintain this relationship through the years, or may prove to the contrary

Custom F2

...

Hilux crossmember drawing

...

F2 axle drawing

...

Quattro radio lid

...

Holiday Buggy motor bracket drawing

...

Quattro resto

...

HitnMiss engine

...

Wild Willy resto

...

Mardave Cobra resto

...

Thunder Dragon resto

...

Grasshopper resto

...

XR311 resto

...

Modded XR311

...

Carbon 25th scratch build

|

|

|

Please Log in to join the conversation. |

Re: Motor wiring conventions 11 years 6 months ago #15074

|

I think you are misunderstanding me. I am saying can we assume that all Tamiya manufactured/supplied motors are wired like that? This is not to get motor rotation "right", but just to get the wiring looking original. A small point I know, but may be important to someone. |

|

Please Log in to join the conversation. |

Re: Motor wiring conventions 11 years 6 months ago #15075

|

Yes, you want it to look right as Tamiya intended it, but the question has raised more questions & answers during investigation. For me in particular, the whole brush spring vs rotation thing has been bugging me for a little while, & this was the ideal topic to find answers.

The quote about wiring colour standards is a general thing - in industry, life in general etc. eg Although for building installations there is now a standard (Brown=live, blue=neutral etc), there is nothing to say what colours should be used for what voltage, polarity etc on anything else. The building regs are a farce anyway as it's only been recently introduced & could lead an unsuspecting electrician into thinking that green/yellow wire is ok to grab hold of, whereas the building may have been wired by a cowbow, before the regs were introduced, & that "safe" green/yellow wire could have anything travelling up it! Anyway, I've got a Grasshopper MSC in my hands at the mo, so I've traced the connections back to see what's what - according to the diagram below (Taken from the Grasshopper manual), when the MSC is in "forward", battery +ve (red) gets connected to green. To me, that suggests that yellow is normally the +ve/hot colour, & that the Grasshopper MSC works back-to-front, clue being the green-yellow/yellow-green MSC to motor connections grasshopper MSC diag.bmp

Custom F2

...

Hilux crossmember drawing

...

F2 axle drawing

...

Quattro radio lid

...

Holiday Buggy motor bracket drawing

...

Quattro resto

...

HitnMiss engine

...

Wild Willy resto

...

Mardave Cobra resto

...

Thunder Dragon resto

...

Grasshopper resto

...

XR311 resto

...

Modded XR311

...

Carbon 25th scratch build

|

|

|

Please Log in to join the conversation. |

Time to create page: 0.184 seconds