TOPIC:

Project "Roughpatch" - SRB/Apache hybrid runner 11 years 2 months ago #17761

|

Some of you may remember my first posts and deliberation about how to restore my very sorry Sand Scorcher - take it back to original or keep it in the "modified" state from my teenage years but tidy it up and make a runner. Well, I now seem to have collected enough SRB bits to do both |

|

Please Log in to join the conversation. |

Project "Roughpatch" - SRB/Apache hybrid runner 11 years 2 months ago #17762

|

Amongst the bits I have "collected" over the last six months or so is a broken SRB rear cage. This had broken (as they all do) at the lower mounting points. It also was cracked across the horizontal brace piece. Surprisingly the aerial mount is still intact. Inspired by Eddrick, I decided to have a go at plastic welding. I found some sprue that looked like the same material and fired up my gas soldering iron.

Before: After some welding - pretty pleased with the result: After a bit of Dremelling and sanding: I have to say it went much better than I could have hoped. The repair seems strong and from a couple of feet away is looks original. With a little more sanding it will stand up to quite close scrutiny. Just need to drill the mounting holes now. |

|

Please Log in to join the conversation. |

Project "Roughpatch" - SRB/Apache hybrid runner 11 years 2 months ago #17767

|

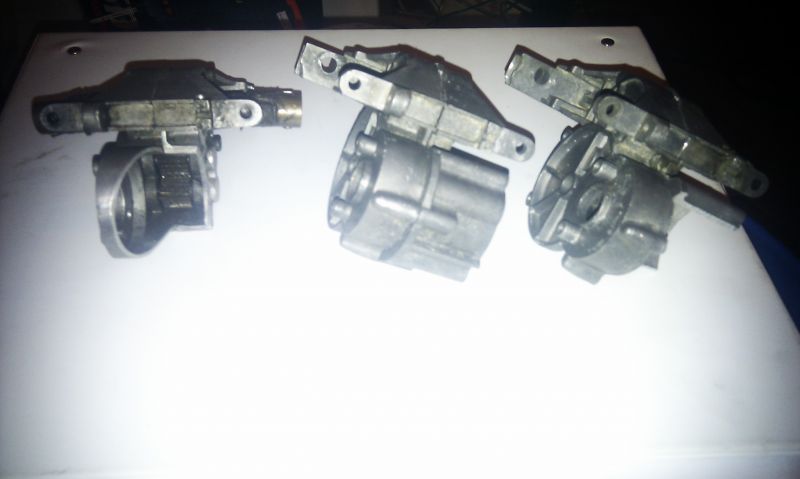

More "before" pics.

"Modified" gearbox Haven't decided whether to replace this or not yet. I have plenty of gearbox casings, but no spare motor or gear covers. Also the rear cage mounting lug is broken. Front end (think I'll lose the bumper) I think I will paint the gearbox and suspension satin black and maybe the chassis too to match the front suspension. Any advice on painting pot metal parts? Mmmm, maybe a Kamtec "carbon fibre" radio box ... |

|

Please Log in to join the conversation. |

Project "Roughpatch" - SRB/Apache hybrid runner 11 years 2 months ago #17769

|

|

|

Please Log in to join the conversation. |

Project "Roughpatch" - SRB/Apache hybrid runner 11 years 2 months ago #17845

|

|

|

Please Log in to join the conversation. |

Project "Roughpatch" - SRB/Apache hybrid runner 11 years 2 months ago #17914

|

Well that was hard work!

(pictured on the "other" chassis) The flash makes the body look whiter than it actually is. Once again I had forgotten how many coats of paint I had applied to the body in my teenage enthusiasm. I counted white, red (boxart I think), black, red, orange, white and grey primer. The second white coat was frustrating because it seemed nearly impervious to the graffiti remover and protected the layers underneath. I am not sure what it was, but I would guess at Hammerite "Smoothrite" White as I was quite a fan back in the day. Now to get some plasticard and fix the holes |

|

Please Log in to join the conversation. |

Project "Roughpatch" - SRB/Apache hybrid runner 11 years 2 months ago #17936

|

You took the plunge then?

Gonna be a cool project this one, methinks! Next time you do some plastic welding, turn the heat down - when it goes shiny or wet-looking, the heat is making the plasticiser come to the surface, which will result in the material going brittle. You need just enough heat to melt the plastic, no more. 15-25 watt electric iron would be more than enough. Best way to do it is with hot air (Or nitrogen), as you get a better quality weld if the heat source isn't in contact with the plastic. Modified hot-air paintstrippers work well (One with variable heat & reducer nozzle) but they're a bit too big for toy cars. Had toyed with the idea of building a tiddly one using an injection-moulding heater cartridge & running it off the airbrush compressor, but then I remembered you can't buy welding rod that's suitably small, making the project a bit pointless... I suspect the "white" may have been some sort of primer (Plastic primer?) as it's usually more resilient to chemical attack. Smoothrite on the other hand, is not. Anything stronger than water will have that off, it behaves like model enamel & will dissolve in paraffin, diesel, petrol, brake fluid, white spirit, cellulose thinners, enamel thinners etc etc

Custom F2

...

Hilux crossmember drawing

...

F2 axle drawing

...

Quattro radio lid

...

Holiday Buggy motor bracket drawing

...

Quattro resto

...

HitnMiss engine

...

Wild Willy resto

...

Mardave Cobra resto

...

Thunder Dragon resto

...

Grasshopper resto

...

XR311 resto

...

Modded XR311

...

Carbon 25th scratch build

|

|

|

Please Log in to join the conversation. |

Project "Roughpatch" - SRB/Apache hybrid runner 11 years 2 months ago #18002

|

My gas soldering iron has a hot air attachment that I use for heat shrinking wires. I might give that a try on some scrap parts.

It is a very useful tool all round actually. I originally bought it for Field Service work as you don't need to plug it in (sometimes have issues with airport security with the aerosol butane refills though. I've had a number of them confiscated I can thoroughly recommend it. |

|

Please Log in to join the conversation. |

Time to create page: 0.180 seconds