TOPIC:

What did you do today? 10 months 1 week ago #75565

|

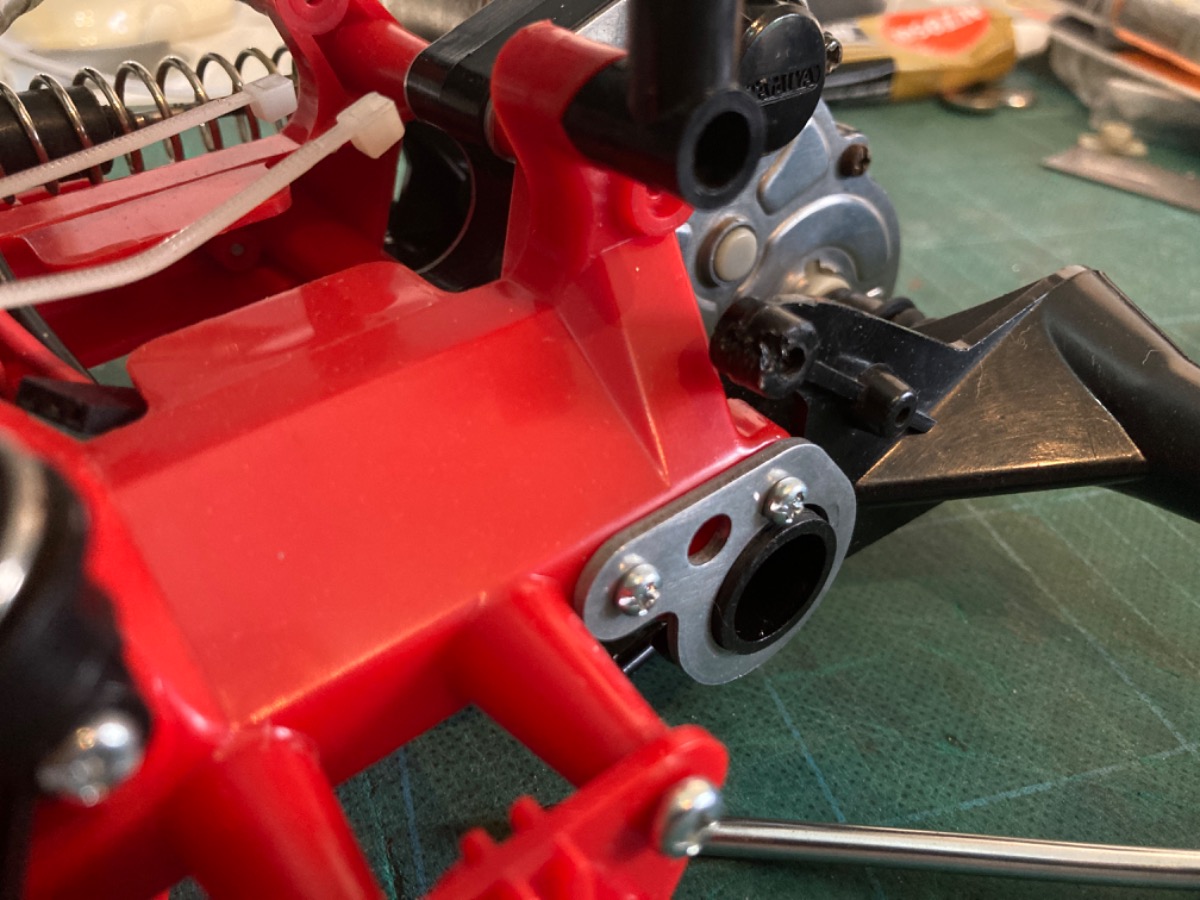

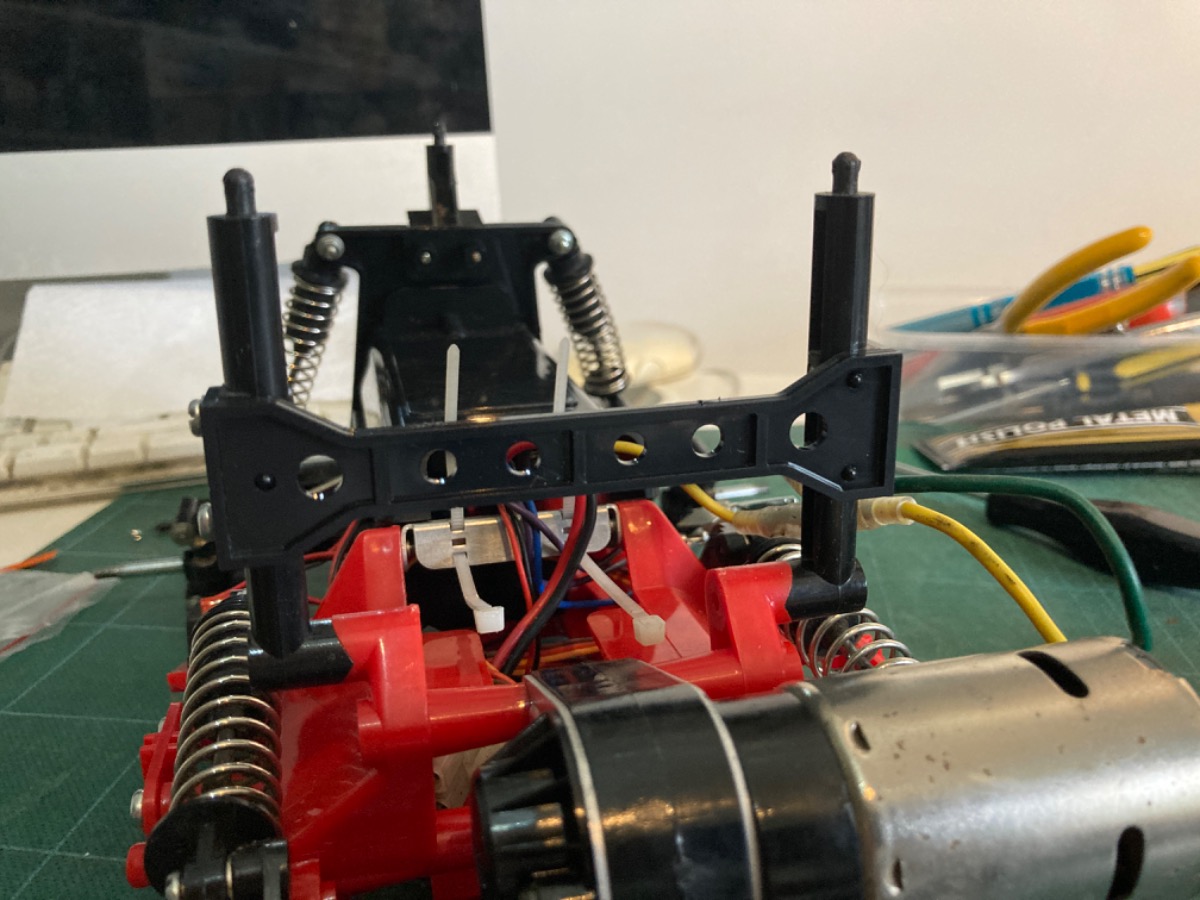

The biggest problem with the ORV chassis is the suspension mounting point on the trailing arms. Rather than buy a new parts tree to replace this one on my Blackfoot, I seriously couldn’t bring myself to spend more money on this part. Instead I thought I’d try fixing it ??? I thought I’d try using a piece of the black plastic from the parts tree and use my soldering iron to melt some more plastic into the crack. I wouldn’t expect it to last long if I gave it a run, but for now it’s slightly better than it was before hand. The screw is at least holding. I also added the last part to finish the build. The brace between the two body posts needed fitting. I had been avoiding buying another whole parts tree just for one piece, but £10 for a whole tree against £15 for the individual part secondhand, I just gave up and bought a whole parts tree. Another small job to tick off. Attachments: |

|

|

Please Log in to join the conversation.

Last edit: by Al.

|

What did you do today? 10 months 1 week ago #75566

|

In addition to what you've done, Al, I woul print a part that goes around and would reinforce it... (this is basically the type of fixes I made to my Hunter chassis' motor mounts...)

I buy kits to built and ru(i)n them

|

|

Please Log in to join the conversation.

Last edit: by silvertriple.

|

What did you do today? 10 months 1 week ago #75568

The following user(s) Liked this: stingray-63

|

|

|

Please Log in to join the conversation. |

What did you do today? 10 months 1 week ago #75569

|

Well, hair line cracks are generally coming from overtightened screws initially. I remember back in the eighties, I had no idea what a JIS screw driver was. Only screw drivers I had at hand was Philips screw drivers... And used with JIS screws, while you are trying to turn the screw, the form of the bit was pushing the screw driver up, which means you had no sense of how much you were tightening the screw... That led to overtightened screws most of the times... And therefore cracks. Further old ABS exposed to UV, cold and hot weather, is not better. That being said, a circle of PETG of 2 mm around the part for 3-4 mm deep should be enough to reinforce the part so it doens'nt crack more than how it is cracked already...

And when it's broken already, it doesn't cost anything most of the times... And you would not mind to break it more if you run the part I buy kits to built and ru(i)n them

The following user(s) Liked this: Lemsko

|

|

Please Log in to join the conversation.

Last edit: by silvertriple.

|

What did you do today? 10 months 1 week ago #75571

|

I had the same issue with my rere brat never run from 2005. And not overtighten. The bushing method is the best one.

The following user(s) Liked this: Al

|

|

Please Log in to join the conversation.

Last edit: by stingray-63.

|

Time to create page: 0.259 seconds